Switchgear Insulation Products

High Voltage Insulation Sheets - BUSSHEET

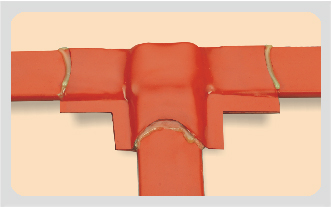

Bus Sheet GMHS & GHHS is an adhesive coated heat shrinkable sheet, which provides insulation enhancement & protection against accidentally induced discharge. It is suitable to insulate almost any sizes or shapes of busbar joint like busbar tees, elbows and other connections where tubing and tape can not be used.

After applying heat, this sheet shrinks to tightly conform to complicated shapes. Gala mastic tape can also be added to ensure that protruding shapes are insulated. The sheet is manufactured from high quality non tracking crosslinked polyolefin material & meets ANSI C37.20.2 standards for MV application upto 36KV. GMHS sheet shall provide flashover protection up to 17.5KV. & GHHS sheet shall provide protection up to 36KV.

STANDARDS :

- Easy to install on site using a gas torch or hot air gun.

- Prevents Busbar from chemical corrosion v effected by strong acid, alkali, salt, etc.

- Halogen free, flame retardant.

- High dielectric strength.

- Excellent UV & weather resistant v properties,& hence suitable for indoor or outdoor use.

- Reduces BusBar Clearance.

- No Special Mould / Tool required.

- Meets IP 68 (ingress Protection)

Technical Qualification Report : QR 1019

TECHNICAL SPECIFICATION

- TEST DESCRIPTION

- RECORDED VALUE

- TEST METHOD

- Physical

- Dielectric Strength

- 12 KV / mm. (min.)

- ASTM D149

- Tensile strength

- 12 N/mm2 (min.)

- ASTM D638

- Ultimate Elongation

- 300% (min.)

- ASTM D638

- WaterAbsorption

- 0.5% (max.)

- ASTM D570

- Hardness

- 45 ± 10 shore D

- ASTM D2240

- Thermal

- Accelerated ageing

- (120°C for 500 Hrs)

- ASTM D2671

- Tensile Strength

- 10 N/mm2 (Mpa) (min.)

- ASTM D 638

- Ultimate Elongation

- 250% (Min.)

- ASTM D 638

- Low temperature Flexibility (-40°C for 4 Hrs.)

- No Cracking

- ASTM D2671

- Heat Shock (250°C for 30 Min.)

- No Cracking or flowing

- ESI 09-11

- Shrink Temperature

- 125°C

- IEC 216

- Continuous Temp. Limit

- -40°C to + 105°C

- IEC 216

- Electrical

- Dielectric Strength

- 22 KV/mm.(min.)

- ASTM D149

- Volume Resistivity

- 1 x 1014 Ohm.cm(min.)

- ASTM D257

- Dielectric constant

- 5 (Max.)

- ASTM D150

- Resistant to track & erosion

- No tracking,erosion or

flame failure upto 3.25

.KV for 20 min. - ASTM D2303

- Voltage

- Medium wall Sheet (GMHS)

- Heavy Wall Sheet (GHHS)

- UN-Insulated Bus bars

- Ph. To Ph.

- Ph. to gr.

- Ph. To Ph.

- Ph. to gr.

- 12KV

- 65

- 75

- 35

- 45

- 120

- 17.5 KV

- 85

- 105

- 55

- 65

- 160

- 24 KV

- 115

- 150

- 70

- 100

- 220

- 36 KV

- 200

- 285

- 140

- 190

- 320

PRODUCT SELECTION

- BUSBAR WIDTH (mm)

- CUT SIZE NEEDED (mm)

- NO. OF INSTALLATIONS PER SHEET

- 25

- 275 x 225

- 8

- 50

- 325 x 250

- 6

- 75

- 400 x 275

- 4

- 100

- 450 x 325

- 3

- 150

- 550 x 425

- 2

- BUSBAR WIDTH (mm)

- CUT SIZE NEEDED (mm)

- NO. OF INSTALLATIONS PER SHEET

- 25

- 275 x 225

- 10

- 50

- 325 x 250

- 7

- 75

- 400 x 275

- 5

- 100

- 450 x 325

- 4

- 150

- 550 x 425

- 2

Note : The above table should be used as a guideline only. Please try with one or two joints before adopting final cut size. The busbars are assumed to be insulated to 25mm. from the joint. Cut size should extend minimum of 100mm. on each leg of the joint before shrinking and should overlap existing insulation by 65mm. after shrinking.

ORDERING INFORMATION

- GALA CODE

- LENGTH Ls (mm)

- WIDTH Ws (mm)

- THICKNESS (Tf)

- SHEET (mm)

- ADHESIVE (mm)

- TOTAL THICKNESS (mm)

- GHHS

- 1200

- 430

- 4

- 1.5

- 5.5

- VOID FILLING MASTIC

- 300

- 60

- PIECE

- SEALANT MASTIC

- 300

- 20

- PIECE

- TOOL - 1

- (BASIC CLAMP AND BRACKET KIT)

- KIT

- TOOL - 1

- (EXTENDED CLAMP AND BRACKET KIT)

- KIT

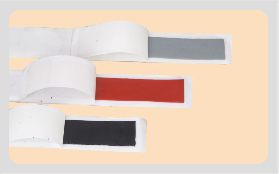

Note : If required, one piece of Red sealing mastic is applied on each leg of the joint and one or two pieces of Black sealing mastic is used to cover uneven shapes.

Products

Heat Shrink Tubes / Heat Shrink Sleeves

- Advantages Of Heat shrink Tubing

- Thin Wall Tubes

- GDW : Dual Wall Tubing

- Medium/Heavy Wall Tubes-Commercial

- Heat Shrink Co-extruded Tubing Premium Quality

- Red Insulation Tubes

- Non Tracking Tubes

- Busbar Sleeves

- Stress Control Tube

- Integrated Stress Control Tube-GVOT Tube

- Heat Shrink Double Layer Tube-GDTL Tube

Switchgear Insulation Products

- Barrier Board Sheet

- End Sealing Kit for Extensible RMU/GIS Bushing

- Heat Shrink Bus Bar Sleeve

- Bus Bar Insulating Shrouds

- Bus Bar Insulating Shrouds Polyolefin

- Bus Bar End Caps

- Thin wall tube wire marking

- Heat Shrink Tape (Bustape)

- Insulation for Circuit Breakers

- Busbar Sleeve for 66 kV

- Bushing Boot

- Non Shrinkable High Voltage Tape

- Heat Shrinkable Gland