Switchgear Insulation Products

Thin Wall Tube - for Wire Marking

Finotube-wire marking / identification is cross-liked polyolefin heat shrikable tubes used for identification and insulation of wire, cable, Terminals and other components

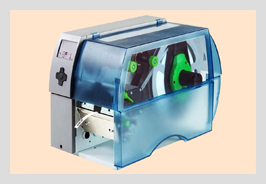

The product is intended for interior and exterior markers. it is recommended for both, dot matrix and transfer thermal printers. the tubes can be printed on both sides for maximum data content and readability.

After shrinking, the imprint is permanent and solvent resistant.

Spcifications

Mil - 1- 23053/5 class 2 & 3, cru us, UL224 (file no. E328538) 1250C VW1

-: General Properties of product :-

- offers Strain relief to the connection.

- versatile applications.

- halogen free, flame retardant.

- remove hassle of keeping stock of different characters for a to z or 0 to 9.

- no need to select single characters like in PVC

- shrink ratio 2:1

- hologen free, flame retardant.

- meet ROHS compliance.

- backwards compatible for most printers

- wide range of size for several wire and bundle diameters.

- standard colours available upon request.

Technical Qualification Report : QR 1031

| Part number /size | Internal Dia. (mm) | Rec. Wall Thickness (mm) | Packing configurations | |

|---|---|---|---|---|

| Supplied | Recovered | Spools Mtr. / Spool | ||

| GSC 4.0/2.0 | 4.0 mm | 2.0 mm | 0.44 mm | 200 m |

| GSC 6.0/3.0 | 6.0 mm | 3.0 mm | 0.56 mm | 150 m |

| GSC 8.0 / 4.0 | 8.0 mm | 4.0 mm | 0.56 mm | 150 m |

| GSC 10.0 / 5.0 | 10.0 mm | 5.0 mm | 0.56 mm | 100 m |

| GSC 12.0/6.0 | 12.0 mm | 6.0 mm | 0.56 mm | 100 m |

| GSC 16.0/8.0 | 16.0 mm | 8.0 mm | 0.69 mm | 100 m |

| GSC 20.0/10.0 | 20.0 mm | 10.0 mm | 0.78 mm | 50 m |

| GSC 25.0 / 12.0 | 25.0 mm | 12.5 mm | 0.78 mm | 50 m |

| GSC 30.0 / 15.0 | 30.0 mm | 15.0 mm | 0.87 mm | 50 m |

| GSC 40.0/20.0 | 40.0 mm | 20.0 mm | 097 mm | 50 m |

TECHNICAL SPECIFICATION

| PROPERTIES | VALUE | STANDARD |

|---|---|---|

| Tensile Strength | 16 N/mm2 (MPA)(min.) | ASTM D638 |

| Ultimate Elongation | 300% (Min.) | ASTM D638 |

| Water Absorption | 0.15% (max.) | ASTM D570 |

| Specific Gravity | 1.40 | ASTM 792 |

| longitudinal change | -10 % max | ASTM D638 |

| low temperature flexibility | -55° | ASTM D2671 |

| flammability | Pass | Ul224 VW1 |

| opereting temerature (-40oC for 4 Hrs.) | -55 to + 125°C | IEC 216 |

| Heat Shock (250oC for 4 Hrs.) | No dripping | |

| Cracking, or flowing | ||

| Fungus Resistance | Inert | Mil - 1- 7444 |

| Copper corrosion | Good | ASTM D2671B |

| chemical resistance | Good | ASTM D2671 |

| Volume Resistivity | >20 KV/mm. (mm) | ASTM D2671 |

| Dielectric Constant | 3.0 (max.) | ASTM D150 |

| Volume Resistivity | 1 x 1014 ohmm.cm (min) | ASTM D257 |

Products

Heat Shrink Tubes / Heat Shrink Sleeves

- Advantages Of Heat shrink Tubing

- Thin Wall Tubes

- GDW : Dual Wall Tubing

- Medium/Heavy Wall Tubes-Commercial

- Heat Shrink Co-extruded Tubing Premium Quality

- Red Insulation Tubes

- Non Tracking Tubes

- Busbar Sleeves

- Stress Control Tube

- Integrated Stress Control Tube-GVOT Tube

- Heat Shrink Double Layer Tube-GDTL Tube

Switchgear Insulation Products

- Barrier Board Sheet

- End Sealing Kit for Extensible RMU/GIS Bushing

- Heat Shrink Bus Bar Sleeve

- Bus Bar Insulating Shrouds

- Bus Bar Insulating Shrouds Polyolefin

- Bus Bar End Caps

- Thin wall tube wire marking

- Heat Shrink Tape (Bustape)

- Insulation for Circuit Breakers

- Busbar Sleeve for 66 kV

- Bushing Boot

- Non Shrinkable High Voltage Tape

- Heat Shrinkable Gland