Thin Wall Tubes

GSC: Flame Retardant Tube

GSC & GSC/YG are Heat Shrink Thin Wall Tubes suitable for below applications :

GSC Series :

- Light duty wire harnessing for electrical & electronic applications.

- Provides electrical insulation and protection for in-line components.

- Used as strain relief for electrical wire connection.

- Bus-bar insulation for switchgear.

- Color coding for wires, cables, terminals and components.

GSC/YG Series :

GSC/YG range of tubing is extremely flexible, flame-retardant, thin wall with yellow and green striped heat shrink polyolefin tubing especially for electrical equipment ground lead applications. The unique dual color striping of yellow and green provides an instant identification for ground wires.

GENERAL PRODUCT PROPERTIES :

- Halogen free, Flame retardant and self-extinguishing

- For Electrical Insulation up to 3.3 kV

- Resistance to chemical, copper corrosion and fungus

- Standard Colors: Black, White, Yellow, Red, Blue,Green and Yellow/Green.

- Shrink ratio 2:1

- UV stabilized

- Meets RoHS Compliance

SPECIFICATIONS :

MIL-1-23053/5 Class 2 & 3,Ul224 (File no.E328193) 125C VW1, CSA C22.2

SELECTION CHART

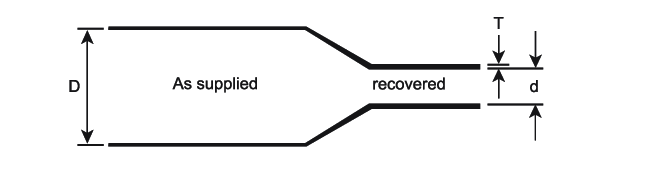

All dimensions are in mm

- Part

- Internal Diameter (mm)

- Recovered Wall

- Packing Configurations

- Number / Size

- Supplied

I.D. (mm) - Recovered

I.D. (mm) - Thickness (mm)

- Spools Mtr./Spool

- Cut Lengths 1.2Mtr./Box

- GSC 1.0/0.5

- 1.0

- 0.5

- 0.28

- 400

- 600

- GSC 1.5/0.75

- 1.5

- 0.75

- 0.32

- 400

- 600

- GSC 2.0/1.0

- 2.0

- 1.0

- 0.35

- 400

- 600

- GSC 2.5/1.2

- 2.5

- 1.2

- 0.44

- 400

- 600

- GSC 3.0/1.5

- 3.0

- 1.5

- 0.44

- 400

- 500

- GSC 4.0/2.0

- 4.0

- 2.0

- 0.44

- 400

- 250

- GSC 5.0/2.5

- 5.0

- 2.5

- 0.56

- 200

- 250

- GSC 6.0/3.0

- 6.0

- 3.0

- 0.56

- 200

- 200

- GSC 7.0/3.5

- 7.0

- 3.5

- 0.56

- 100

- 200

- GSC 8.0/4.0

- 8.0

- 4.0

- 0.56

- 100

- 175

- GSC 10.0/5.0

- 10.0

- 5.0

- 0.56

- 1000

- 150

- GSC 12.7/6.35

- 12.7

- 6.35

- 0.56

- 100

- 120

- GSC 14.0/7.0

- 14.0

- 7.0

- 0.69

- 100

- 100

- GSC 16.0/8.0

- 16.0

- 8.0

- 0.69

- 100

- 100

- GSC 18.0/9.0

- 18.0

- 9.0

- 0.69

- 100

- 80

- GSC 20.0/10.0

- 20.0

- 10.0

- 0.78

- 100

- 65

- GSC 25.0/12.5

- 25.0

- 12.5

- 0.78

- 50

- 40

- GSC 30.0/15.0

- 30.0

- 15.0

- 0.87

- 50

- 30

- GSC 40.0/20.0

- 40.0

- 20.0

- 0.97

- 50

- 20

- GSC 50.0/25.0

- 50.0

- 25.0

- 0.97

- 25

- 15

- GSC 60.0/30.0

- 60.0

- 30.0

- 0.96

- 25

- 15

- GSC 70.0/35.0

- 70.0

- 35.0

- 1.10

- 25

- 10

- GSC 80.0/40.0

- 80.0

- 40.0

- 1.27

- 25

- 10

- GSC 100/50.0

- 100.0

- 50.0

- 1.17

- 25

- 5

* Code for Y/G Striped Tubes - GSC/YG

Technical Specification

- PROPERTIES

- VALUE

- STANDARD

- Physical

- Tensile Strength

- 9 N/mm2 (Mpa) (min.)

- ASTM-D-638

- Ultimate Elongation

- 300% (Min.)

- ASTM-D-638

- Water Absorption

- 0.15% (Max.)

- ASTM-D-570

- Specific Gravity

- 1.4

- ASTM-D-792

- Longitudinal Change

- -10% (Max.)

- ASTM-D-638

- Thermal

- Operating Temperature

- -55oC to + 125oC

- IEC216

- Heat Shock (250oC for 4 hrs)

- No dripping, Cracking or flowing

- Low Temperature

Flexibility

(-550C for 4 hrs) - No Cracking

- ASTM-D-2671

- Flammability

- Pass

- UL224 VW1

- Chemical

- Fungus Resistance

- Inert

- MIL-1-7444

- Copper Corrosion

- Good

- ASTM-D-2671-B

- Chemical Resistance

- Good

- ASTM-D-2671

- Electrical

- Dielectric Strength

- >20kV/mm

- ASTM-D-2671

- Dielectric Constant

- 3.0 (Max.)

- ASTM-D-150

- Volume Resistivity

- 1x1013 Ohm.cm (Min.)

- ASTM-D-257

Products

Heat Shrink Tubes / Heat Shrink Sleeves

- Advantages Of Heat shrink Tubing

- Thin Wall Tubes

- GDW : Dual Wall Tubing

- Medium/Heavy Wall Tubes-Commercial

- Heat Shrink Co-extruded Tubing Premium Quality

- Red Insulation Tubes

- Non Tracking Tubes

- Busbar Sleeves

- Stress Control Tube

- Integrated Stress Control Tube-GVOT Tube

- Heat Shrink Double Layer Tube-GDTL Tube

Switchgear Insulation Products

- End Sealing Kit for Extensible RMU/GIS Bushing

- Heat Shrink Bus Bar Sleeve

- Bus Bar Insulating Shrouds

- Bus Bar Insulating Shrouds Polyolefin

- Bus Bar End Caps

- Thin wall tube wire marking

- Heat Shrink Tape (Bustape)

- Insulation for Circuit Breakers

- Busbar Sleeve for 66 kV

- Bushing Boot

- Non Shrinkable High Voltage Tape

- Heat Shrinkable Gland