Ease of installation, ruggedness and resistance to environmental factors are the basic characteristics of various electrical accessories such as insulation covers, touch proof terminations consisting of screened separable connectors, etc. The insulation cover or blanket is designed to give a perfect fit around different types of valves, piping, transformers, etc. whereas the screened separable connectors help to provide a low tension and high electric strength.

Brief on Insulation Covers

Insulation covers or blankets help maintain process temperature, protect machine components from environmental stress and give highest level of insulation thus ensuring long product life. They not only protect the product but also the personnel working on the machines. Insulation covers reduce undue stress on the machinery and offer increased energy efficiency. These blankets also aid in effective process control by keeping checks on process temperatures, flow of the material, levels of ingredients in the process, etc. Overall they help in making the process cost effective.

An insulation cover is either tight fit or removable. Even the tight fit covers are removable and replaceable. They ensure a complete covering and are highly long lasting. Customized insulation blankets can be designed by studying the facility, evaluating the process parameters and ensuring they increase the efficiency.

Brief on Screened Separable Connectors

Functional Parameters

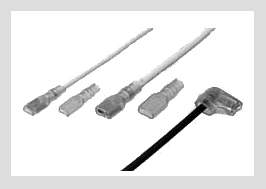

Connectors are an electro mechanical device for joining and making the electrical terminations touch proof. They consist of a male component viz. Plugs and the female component viz. Jacks. The screened separable connectors are made of silicone EPDM rubber. They connect cables to switch gears, transformers and other equipment. These connectors are protected by touch proof outer screen making them fully insulated, submersible. The fully screened connection makes mating with both A and C type bushings possible. Their design is compact, finish is smooth, current capacity is high to the tune of 250A, 630A to 1250A and performance is effective. Their voltage ratings are 11KV, 15KV, 24KV, etc. Using these connectors both ends of the cable are terminated sometimes using identical connectors or at times terminated differently.

Installation

The screened separable connectors are easy, safe and quick to install due to their optimized design and selection of material. They fit into smallest of installation spaces and even when the clearances for operation is insufficient.

Characteristics

Connectors are a physical interface and they should be of a proper size, offer good resistance, give proper insulation, show ruggedness, should be resistant to water, pressure and other factors. Their reliability, durability and ease of installation determine the area of usage.

Applications

These connectors find usage in a wide range of industries like electric substation, underground distribution, shipping, mining, oil and gas, railways, etc.

Summarizing

Screened separable connectors make the terminations touch proof and the insulation covers provide utmost electrical safety. The installation, operational and performance qualification of these accessories must be well documented to ensure compliance with regulations. Onsite training and documentation of the same is also a requirement for safety compliance.