Paper-insulated cables are slowly being replaced by new cable systems which are of the polymeric type. However, there are yet a considerable amount of underground networks following the old technology. Though every new cable installation follows the new technology the old paper-insulated systems will be phased out slowly and till then they will need to be repaired, replaced or diverted in the times to come. This is where transition joints come into the picture. The important work of connecting the new and old cable technology is done by them; they act as a vital bridge between the two systems.

Transition joint is used at all levels of voltage and help to connect varied insulation materials as well as constructions pertaining to cables. So, connecting a three core cable to single core cable is possible through them. Varied screen designs, conductor materials, cross sections of cables are connected perfectly by them. Considering their key role, the main factor in the design of a transition joint is attaining greater amounts of flexibility that will help to satisfy as many requirements as possible with one product more than the price factor.

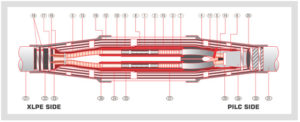

The main constituent of the transition joint is the connector and it is this component which aids in connecting varied conductor materials and sector or round-shaped stranded or solid conductor types. Presence of a separation wall is compulsory for paper-insulated cables as that will prevent spread of any fluid compound within the conductor from the old cable system to the other.

In the process of linking the earlier paper-insulated cables with the new polymeric ones at all levels of voltage it is essential to convert the paper cable into a ‘quasi-polymeric ‘kind. For this the paper-insulated cable end has to be tightened for whatever it’s soaking medium is, oil; or any other compound that may be draining or not. This oil tightness can be attained with heat shrink oil barrier tubing. Use of cold-shrink devices is not very feasible due to the high pressure of the soaking compound that occurs because of variations in cable load.

Joint insulation can be done in case of all types of installation technologies ranging from heat-shrink to slip-on to cold-shrink to cast resin or any other specific method. Transition joints help to connect almost all types of MV cables whether three-core or single; polymeric or paper type. The transition joint’s construction for different levels of voltage is determined by the application it is used for. For example, in a low voltage situation, heat-shrink or cast resin joint are utilized for the switch from three-core paper insulated cables that are mass-impregnated to polymeric cables belonging to the three-core type. At medium voltages, heat shrink transition joints are largely used for connecting a majority of polymeric cables with differing types of paper-insulated cables. In case of high voltages the construction of the transition joint has to be customized. In addition to these, there are various other specific solutions to address a varied range of applications available in the market.

All in all transition joint plays an important role in facilitating cable terminations and jointing functions.