Cable joints form an important part of any electrical system as they connect power cables and provide a continuous flow of electricity to households and industry. Electricity is required in wide ranging applications and hence power cables come in varied shapes, sizes and configurations. Accordingly a wide array of joints is needed to connect the varied type of cables. So, you have the transition joint, PILC joint, branch joint and others used at varying times in any electrical process.

The kind of joint that will be suited for any application depends on a number of factors. Their basic structures differ depending upon the manner in which the two cables have to be connected. Sometimes it is necessary to connect two power cables at a single point while at other times it is essential to accommodate the branching of a cable or it’s entering into the main line. In the former case, the appropriate option is the straight through joint while the branch joint proves useful in the latter option. Branch joints are suitable for cable jointing in varied environments whether it is the indoor, outdoor, submerged or underground jointing. They are of two types; the ‘Y’ type or the ‘T’ type. Straight joints on the other hand enable extension of cable pieces in all industrial or commercial applications.

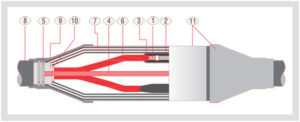

Cables too vary in many respects; there are the old technology based paper-insulated cables alongside the new polymeric type of cables. In this context, the transition joint plays an important role. The job of connecting the old cable technology with the new is done through the transition joint. A three core cable can be securely connected to a one core cable with the help of a transition joint. Achieving compatibility with the relevant cable’s insulation is of paramount importance.

Power cables come in single or multiple cores. However, for compatibility the number of cores of the cable joint has to be the same as the number of cables it is supposed to connect. Similarly the cable voltage and that of the cable joint needs to be the same.

Cable joints perform a very vital function of offering reliable electrical insulation and also provide the necessary strength, physical and mechanical protection to the cables. They are an indispensable component in the electrical system of any industry or household. Varied type of joints like the PILC joint, branch joint, transition joint and others come into the picture when the need arises for making electrical connections. These can be made by means of crimping, soldering, mechanical connectors and so on. Customized cable joints are also available to satisfy specific requirements of the client.

With such an important role to play, it is essential that the cable joints fulfill the standards laid down by the industrial associations. The role of reputed manufacturers is significant as they ensure that all their production facilities are geared towards manufacturing top quality products. Specialized equipment, expertise, latest technology and economies of scale are present at their production facilities which enable the customer to obtain their items at cost effective prices.