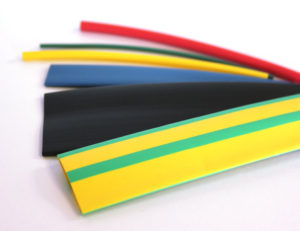

Heat shrink refers to a form of plastic tubing that has amazing properties. It has in fact become the hero material in electrical, automotive, networking and varied other industrial applications. And the process of manufacture of this tubing is determined by the application it is intended for. So you have heat shrink tubes with heavy duty walls which can also go as thin as micro-sized walls to suit the demands and needs of different customers.

Wide Ranging Uses

The uses of heat shrink tubes are wide ranging and include safeguarding connections, wires, conductors, terminals against vagaries of weather; color coding the wires; restoring insulation on cables and acting as a sealing shield against environment hazards.

Role of Heat Shrink in Context of Unused Cables

Offering protection to the ends of unused cable wires is one of the biggest advantages offered by heat shrink end caps. There are two types of varieties available for this application; one which has a film form coating and the other is one with spiral form coating. The former one is useful in the case of pressure cabling while the latter one proves apt in the context of unpressurized cables as well as cables like PVC, XLPE and PILC. The cable end sealing caps have cross linked base material made from thermally stable polyolefin. An inner coating of polyamide adhesive and additional compounding through chemical additives helps to give the required protection to wires against oxidation, ozone and ultra-violet radiation. Insulating and sealing the splice terminations and wires and thus acting as a protective shield against corrosion, moisture, abrasion and chemicals goes a long way in enhancing their life.

Role of Heat Shrink in Preventive Maintenance

Physical stresses inflicted on terminals or connectors by flexing and bending can be easily surmounted by fixing heat shrink tubes on to them. The bending and flexing actions often lead to deterioration of the cable’s conductor layer insulation. The tubes not only offer strain relief but also offer an extra insulation layer. Its incredible features make it an important inclusive tool for circuit boards, terminations and connections.

Importance of Making a Correct Choice

There is a multitude of varieties of heat shrink products in the market and choosing an apt one for your application can be quite overwhelming. However, there are a few factors that have to be kept in mind before making your choice such as your size requirements, temperature and voltage ratings, rigidity and thickness of the wall, heat shrink ratio etc. Choosing the product from a reputable manufacturer is also an important consideration as that will determine the life of the components you have chosen. A reputed manufacturer alone will provide you good quality at affordable prices. It is therefore, necessary for you to search one of the best companies to obtain value for money spent.

On a Concluding Note

Heat shrink products are capable of outperforming traditional insulation forms due to their superior features. They are durable, easy to install, offer effective heat resistance and provide a best fit for cables ensuring their long life.