The extreme installation environments like the underwater, underground, sunlight, humidity, chemicals affected etc need extra precaution to keep the installations corrosion free and long lasting. The corrosion protection tubes are designed to keep the pipelines, cables, joints and molded products corrosion free for the years to come.

These tubes provide not only the corrosion protection but the thermal insulation also. The corrosion protection sleeves, manufactured from the premium grade polyethylene and adhesive materials, provide excellent jointing with the surfaces. The excellent properties like durability against chemical attack, soil stress and abrasion make the use of corrosion protecting tubes the must to improve the quality and life of installations.

Salient Features of Heat Shrink Corrosion Protection Tube:

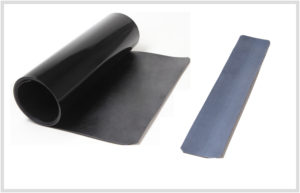

The heat-shrink sleeves are made of thick extruded polyolefin sheet formulated to be cross- linked. The adhesive of heat-shrink sleeves sticks the sleeves to the factory-applied coating and material working as the corrosion protective cover. The heat-shrink sleeves are being used also for getting extra protection against mechanical and abrasion stresses also. Heat -shrink corrosion resistant sleeves provide mechanical and corrosion protection better than the mainline coating. Improved resistance to UV rays, heat, vibration, harsh environmental conditions and sand-blasting is the value added property because of which corrosion protecting tubes are getting place in innovative applications also besides the conventional applications.

These are equally useful in dry and wet underground conditions. The elastomeric characteristic allows a firm conformance over the irregular contours. The shrink ratio is 3:1; it means the users need less sizes to cover the wider range of pipes, cables, joints and products. For the regular bulk buyers of corrosion resistant sleeves, customized length, colors and dimensions are made available.

Range of Corrosion Resistant Sleeve for Different Applications:

• Heat Shrink Thin Wall Tubes: Used for electrical & electronics applications including bus-bar insulation

• Medium Wall Tubes (GMW): Used for environmental and mechanical protection of low voltage electrical cable termination as well as for insulating the low voltage joints/splice/connectors rated up to 3.3KV.

• Corrosion Resistant Heavy Wall Tubes (GHW): Used for polyolefin cable joints/splice/connectors up to 36KV.

• Dual Wall polyolefin Tubing for Corrosion Protection: Used as waterproof barrier and corrosion protection cover for electrical, automobile & communication, molded components & cable breakouts

• Corrosion Resistant Non Tracking Tubes: Used to protect medium voltage cable joints and end terminals/ joints

As the demand of heat shrink rust protection tubes is increasing in vivid industries, the leading heat shrink corrosion protecting tubes manufacturers are expanding the customized range also helping the users to protect their products and installations elegant looking, environment protected, insulated, chemical resistant, corrosion resistant and long lasting. Apart from the wide range of rust resistant heat shrink tubes, the wide range of heat shrink molded sealing caps is also available.

Concluding Note:

Buying the perfect corrosion protection heat shrink tube depends upon how perfectly you convey your requirements. It is important to share the complete details of intended application. The qualified and experienced technical customers support engineers of corrosion protection tubes supplier recommend the best suitable rust protecting sleeve. The available sizes of each category are also tabled at the business website to help you optimize the requirements on the basis of cut lengths, spools meters, internal diameter (supplied and recovered) and recovered wall thickness.