Busbars are an important part of any electrical power distribution system. The term is used to denote a thick strip of aluminium or copper that helps in conducting electricity within a distribution board, switchboard, battery bank, substation or any electrical apparatus. They are useful in transmitting large current loads or distributing current to several devices.

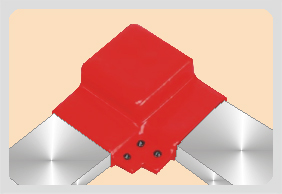

Using the appropriate busbar for the existing current in the given electrical setting is of utmost importance. There are several items that fulfil this need such as the busbar boots, busbar sleeve, busbar insulation shrouds and busbar connection shrouds in the industrial electric industry. Busbar boots is a flexible, plastic moulded insulated shroud that offers protection for switchgear and busbar connections. The busbar insulator shrouds or boots are utilized for coating metals as well as other conductors so as to decrease or stop the electrical current flow when needed and avoid fires, shocks and short circuits. These are reusable electrical insulating coverings and are mainly made from polyvinyl chloride material which works well for high voltage electrical applications. Busbar heat shrink sleeve protects, insulates or shortens the distance of busbar, after shrinking. For choosing the right kind of busbar sleeve, it is essential to know the voltage resistant level and the size of the busbar. In addition to standard sizes, customized busbar sizes can also be obtained.

All busbar items primarily promote electrical safety and prevent the occurrence of voltage related injuries. Their advantageous features can be listed as below:

- Enormous dielectric strength

- Can be installed and removed with ease

- Great resistance to ozone and UV rays

- Offers substantial drop in air clearances

- Excellent thermal and electrical properties

- Availability of tailor-made designs to suit any connection or shape

- Low tooling costs

- Manufacture of large parts with low tooling investment

There can be no compromise on the workers safety in any industrial setting and those who need to deal with high voltage switchgear have to essentially follow all measures that control electrical hazards. Installation of busbar boots helps in maintaining a safe distance from energized components and goes towards ensuring worker safety.

Copper is predominantly used in the manufacture of busbars though they are also manufactured from aluminium and cuponal. The metal is chosen depending upon the needs of the application. Aluminium is cheaper than copper but has to be handled with more care while installing. However, aluminium becomes the preferred choice in applications where lightweight connections are of paramount importance as in the case of aerospace and rail industry. Here, aluminium busbars are used for electrical panel boards, transformers or distribution boards. Cuponal is another useful option when it comes to the transformer and marine industry sectors.

It is beneficial to get all your busbar requirements fulfilled from a manufacturer who specializes in its production. The manufacturer has specialised equipment, latest technology, expertise and economies of scale that help you in obtaining these products at cost effective prices. Certain extra services like customized sleeving, assembly of insulators and earth bars, electro plating in tin, zinc finishes are provided by most of them. So, always buy your busbar requirements from a reputed and specialized manufacturer and see that they will last for longer periods of time.