Power cable accessories play a significant role in distribution of power and it is therefore essential to ensure that you have the right one for the right application. Different products have their benefits and drawbacks in addition to different quality standards adopted by different manufacturers. Ensuring a good quality and a perfect fit for the application guarantees the effective functioning of the cable accessories.

Reputed manufacturers spend sums of money on research and development so that they develop cable accessories that offer long-term performance. Their products are reliable and give peak performances even in utmost stringent conditions including situations of high electrical, environmental and thermal stress. Cable accessories from reputed manufacturers are based on technology of molecular cross-linked polymers. These are endowed with elastomeric shape memory. Cross-linked products are superior to non-cross-linked ones in terms of chemical, thermal and mechanical resistance. These accessories stand apart from the others due to their:

- Enhanced sealing and insulating features

- Better mechanical toughness

- Resistance to chemicals and weathering

- Endurance to alkaline soils and UV radiation

- Availability of large shrink ratios

- Longer shelf-lives

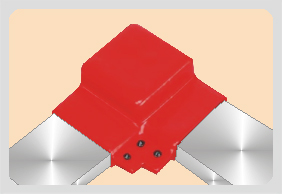

Product lines are comprehensive comprising of cable joints, sealing systems like busbar boots, busbar tubes; outdoor and indoor terminations, universal insulation, repair systems and so on. Accessories working at medium voltage levels have stress control coating integrated into their insulating tubing. The insulating tubing acts as an environmental sealant to cable lug in terminations besides offering erosion resistant and non-tracking surface.

Heat shrink products which comprise a large part of the cable accessories are easy to install with a propane gas torch being the only requirement. When used the heat shrink parts are sufficiently stretched to slid snugly over the cable and safeguard it from environmental and chemical factors. The underlying adhesive liquefies to plug all voids and grooves. The accessories begin to function right after they are installed. Installation related hazards are done away with by avoiding work of soldering. There are no issues of damaging or dirty residues which otherwise would need to bear additional disposal costs. Emphasis is laid on use of as much of eco-friendly material as possible by manufacturers of sound repute. Awareness of social responsibility is uppermost in their minds.

As to quality of the products, reputed manufacturers do not bring any of their products to the market without them undergoing stringent testing on several parameters. They ensure that their products are in conformity with leading national and global standards. Monitoring of quality standards right from the raw material stage to the end packaged stage is done and documented. Because of having good quality systems in place these manufacturers obtain re-certification under international standards.

All the power cable accessories are provided with the requisite instruction manuals and come along with related electrical insulation materials. Reputed manufacturers take customer feedback seriously and continuously strive to achieve maximum customer satisfaction.

There can therefore be no compromise on the cable accessories’ manufacturer’s reputation. It is worth to pay a little extra if you are going to be assured of quality and reliability of your cable accessories.