Busbar systems had been introduced as a superior alternative to conventional power distribution systems and have been quite successful in resolving several issues connected with the cables. Busbar trunking systems use aluminum or copper conductors for the purpose of power distribution around a building and are slowly becoming the preferred choice for a large section of the construction industry. Following reasons make it clear.

Space Saving

Busbar systems have compact design and therefore require lesser space as compared to cable systems. The attribute of compactness enables the tightly packed in conductors to remain reliable and isolated. The messy tangle of cables is avoided because of the sleek and compact design of the busbar systems.

Flexible Nature

The modular design of the busbar ensures that they can be fitted into any structure. Moreover, relocation is easily possible without incurring large expenditure. As against this, relocating, expanding or reconfiguring of cable systems is very costly and disruptive as far as customer service is concerned. The reconfiguration, replacement or addition of busbar can be done with minimal interruption of customer service.

Superior Resistance

Superior resistance is offered by busbar compared to cables and this is proved more so in short circuit testing. The presence of a thin flat tire endows the busbar with lesser density levels helping in optimal dissemination of the density of current. Consequently, loss of voltage is much less from a busbar as compared to that of cables.

Economical in Long Run

Busbar is normally associated with higher costs but it is not really so! The configurable system and ease of installation ensure the busbar’s competitiveness as costs of material handling and assembly time are greatly reduced. The system requires minimal maintenance and hence proves economical in the long run as compared to the cables.

Future-Proofing

The flexible nature of the busbar system helps in adapting it for change of use in the future. Modifications can be made in the future as per client requirements without the need for additional cables which can prove expensive and time consuming. This attribute of flexibility gives the necessary assurance to the client that his busbar system will work efficiently for years to come.

Quick & Safe Installation

The ease and simplicity of installation of busbar systems helps in reducing on-site expenses. Cables on the other hand require larger manpower and time hours for installation on site. Specialized electricians are needed for the installation of cables while about 10 meters of busbar can be installed by the installers with great ease at a time without the need for special tools. The accessories, joints and lengths are just screwed or bolted with one another.

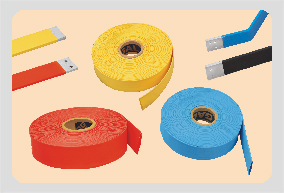

Role of Heat Shrink Products

There are some components that play a vital role in these busbar systems and they are the heat shrink products such as heat shrink tubes, busbar tubes and so on. These products offer superior insulation and consistent performance even at constant high operating temperatures. On provision of heat, these products fit securely over the busbar profile thus obtaining the minimum wall thickness.

Busbar systems have major advantages over cable systems and are value worth the money spent!