Imagine the mess in our homes and offices if the cables and wires were not bundled and coded neatly and instead were left loose in an untidy fashion? Navigating through them would have made work truly difficult and cumbersome. However, the presence of cable accessories has ensured that this is not the case in any home or commercial setting.

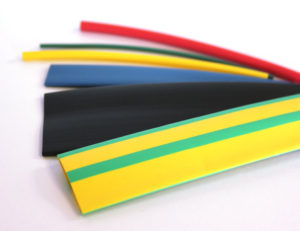

Cable accessories have indeed proved a boon in household and commercial applications offering protection to the electrical systems and making work more easy and convenient. The hero in this context, the heat shrink products like heat shrink tubes, heat shrink boots, heat shrink end caps, and many more form an important part of the cable accessory arsenal.

Heat shrink products are largely made of nylon, polyolefin, fluoropolymers, etc. and they give a snug protective fit to the cables and wires by contracting on being heated. Polyolefin is a preferred material in many cases as it is flame-retardant and is endowed with excellent electrical, chemical and physical properties. The required heat is provided in most cases by means of a heat gun. The extent of shrinkage on the application of heat is explained through the shrinkage ratio. This varies from product to product, for example, it can range from 4:1, 3:1, 2:1 and so on. In a 2:1 ratio, the product will become half of its original size whereas in a 3:1 ratio the original size will be three times larger than the contracted form.

Heat shrink end caps are shaped in the form of small mugs and they fulfill the same function just like any other heat shrink product. Insulating wires and cables and offering a snug protective cover in addition to color-coding the network of cables and wires are some of the important functions performed by them. Sometimes, heat shrink products have an adhesion lining of thermoplastic which comes with superior sealant features and thus offers total safety.

Chemical, fungi, water and the heat resistant property of these products enable them to safeguard the cables and wires underneath from environmental stresses. Ease of installation and maintenance of the heat shrink products makes them a preferred choice in many industrial applications. Some of the important factors that have to be considered when choosing the heat shrink product include the diameter of the cable or wire bundle, the temperature range needed by the application and the shrinkage ratio of the product.

The reputation of the manufacturer also counts a great deal while making your choice. All reputed manufacturers stock ISO certified products that need to be purchased as they guarantee safety in use. The installation of the product has to be done as per the instructions of the manufacturer. After the products have been installed its operation has to be monitored at the stated specifications and verified three times. It is essential to document the entire process.

Heat shrink products have become indispensable in industrial settings. They not only offer protection to all the electrical devices but also enhance their aesthetic appeal. The world has truly become a safer place to live in due to these!