Corrosion is a vital concern for the engineering workforce while taking on any project in industrial and commercial settings. If neglected, corrosion in metal pipes and bends tends to cause accidents, disasters, and financial loss. The exposure to the surrounding environment works as a catalyst to degrade the metallic pipes, joints, and bends used in installations and manufacturing. The numbers of techniques are used for corrosion protection in pipes and joints but heat shrink Polyolefin tubing is emerging as the most favorite choice of engineers engaged in installation and manufacturing activities in electrical, coastal, marine, industrial, oil and gas product like sectors.

Corrosion is a vital concern for the engineering workforce while taking on any project in industrial and commercial settings. If neglected, corrosion in metal pipes and bends tends to cause accidents, disasters, and financial loss. The exposure to the surrounding environment works as a catalyst to degrade the metallic pipes, joints, and bends used in installations and manufacturing. The numbers of techniques are used for corrosion protection in pipes and joints but heat shrink Polyolefin tubing is emerging as the most favorite choice of engineers engaged in installation and manufacturing activities in electrical, coastal, marine, industrial, oil and gas product like sectors.

What is Heat Shrink Cross-linked Polyolefin Corrosion Protection Tube?

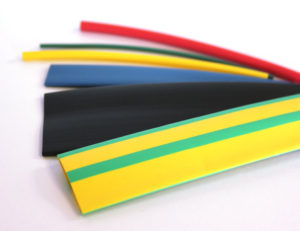

Cross-linked Polyolefin, also known as XLPO, is an excellent insulation created through heat and high pressure. Heat shrink technology adds new properties to Cross-linked Polyolefin. Because of being highly flexible, Cross-linked Polyolefin corrosion protection sleeves are finding new applications in commercial, industrial, manufacturing, military installations, R&D, and others for corrosion protection. Exceptional resistance to moisture, water, fungus, chemicals, flame, and UV light makes Polyolefin an increasingly used electrical insulation material also having the dependable corrosion resistant property. Therefore, heat shrink cross-linked polyolefin tubing is good for corrosion and electrical insulation. As the awareness for using the best quality pipeline/corrosion protection products is increasing, the leading corrosion protection tube brand, ‘Gala Thermo’ is expanding its products range also.

Pre-Insulated Pipe Sealing Cap:

Heat shrink pipe sealing cap is made with hot melt adhesive to seal and protect the joints of pipelines exposed to the hazardous environment. Heat melt adhesive lining provides exceptional environmental protection against moisture, contamination, and environmental conditions up to the IP 68 standards. Thickness of sealing caps varies from 2.0 to 3.5 mm.

Corrosion Protection Sleeves For U-Bolt Coating:

U-bolts are the small but vital part of any mechanical structural designs applied to refineries, chemical plants, large manufacturing units, and other commercial spaces. Over the years, the contact area between pipe and un-coated U-bolts starts eroding and deteriorating the material because of the presence of chemicals, gases, moisture, and other factors. The corrosion is a very common cause of pipeline and structure failure. Heat Shrink Polyolefin tubes for u-bolt coating now available in a wider range help you chose the best fit for the particular application.

Heat Shrink Polyolefin Coupler for Long Lasting Pipe Connection:

The coupler is a small heat shrink tubing suitable to joint corrugated HDPE pipes in a highly corroding environment. Engineers associated with water management, sewage and drainage, irrigation, sanitary, construction, ducting, underground cabling, mining industry like projects essentially use Polyolefin couplers to make the pipe joints long-lasting. Besides being the most economic pipe jointing solution, it has a superior elastomeric characteristic that allows uniform conformance over the irregular

contours. Gala Thermo offers the range of corrosion protection tube couplers in customized lengths, colors, and dimensions.

Concluding Note:

Polyolefins are heat resistant, durable, and resistant to most kinds of chemical corrosion. Because of being non-toxic, these can be used to make the piping corrosion resistant in food processing and healthcare industries also. Heat shrink technology complements the characteristics of Cross-linked Polyolefin to make it the best choice for corrosion protection tubes to meet out the diverse needs in environment-sensitive installations.