In the electric power connections and distribution, busbar plays as the conductive material role that is assembled for distributing the electric power from the main supply point towards the number of other output circuits easily and with flexibility. For any of the distribution assembly, the busbar is known as the true backbone.

So what are exactly busbar sleeves?

Busbar sleeves are made and manufactured according to the rigidness for providing higher support to its own weight and numerous forces imposed due to any mechanical vibration and also the electronic mechanical forces that occurred during the short circuit. And the insulated busbars are overall completely enclosed with the metallic enclosures of aluminum or GI.

The thing to know –

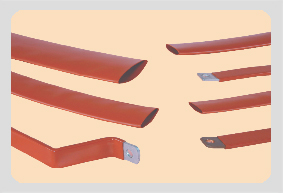

Busbar is useful in many configurations and so it comes in a various magnitude of shapes as well as sizes like solid bars, flat strips, or rods which are commonly made up of aluminum, copper, and brass. Its cross-sectional size and material composition let us know the amount of current which can be safe to carry by the busbar sleeves.

There are few points to be remembered while choosing an electrical bus bar type like –

- Very simple design as per the requirements.

- There must be provision for maintaining without any interruption of power supply.

- If the load on the system rises, then there should be a wide scope of extension.

Why are busbars popular?

Busbars are famous because of its –

- Low facility costs – The busbar sleeves installation is cheaper if compared to others, and there are no other labor costs for any electrical specialists. It does not require routine maintenance and is inexpensive for expansion or remodeling.

- Easiest and quickest installation – Installation of Busbars is quicker and easy with zero downtime.

- Eco-friendly – Based on the type, Busbar Insulation Shrouds need only a few insulation materials, as well as plug-in outlets and, are re-locatable and reusable.

- Very much secure and reliable – It replaces the cable terminations that have its own complication of fire risk.

What are the applications of Busbar?

The main or say basic applications Busbar Insulation Shrouds are –

- Industries

- Data centers

- Laboratories

- Apartments

- Industries

- Power plants

- Hospitals

- Metros

- Railways

- Technology settings

- Retail services

- Institutions

Different types of busbar arrangements!

Busbar comes in round, cross-sectional, and round in shape and many different shapes. In the power system, the rectangular bus bar is many times used. Almost, it is made up of aluminum, copper, and brass, that is the wide range of busbar arrangement which is useful for distribution of power. The option for arrangement of busbar relies on various factors but is not limited to reliability, usage, flexibility or cost, etc.

The different types of busbar are –

- Lightning

- Sandwich

- Cast resin system

- Compact air insulated

- Trolley busbars

- Segregated phase bus ducts

- Isolated phase bus ducts

- Non-segregated phase bus ducts

So while choosing busbars, make sure to check its highest temperature, size, VAC rating, and amp rating. As it is equally important for knowing properly if you require to buy the cover or an enclosure for the busbar system or not.