Heat shrink technology is evolving fast as its future promising benefits are being noticed and certified by the technology experts. Heat shrinking has changed the entire safety landscape in electrical installations because of the effectiveness, performance, longevity, and the cost-efficiency of heat shrink electrical accessories.

Five Heat Shrink Accessories for Electrical Installations:

1. Heat Shrink Tubes: These are increasingly finding a place in electrical cable protection. Manufactured from cross-linked polyolefin, these are fitted around the electrical cables. The sheathed area is heated with a hot air gun and the tube shrink fits to cables. Protection from the environmental hazards, shock, chemicals, heat, and stresses is the key advantage in addition to easy identification.

2. Heat Shrink Cable End Caps: These are used to seal the ends of heat shrink cable ends for protection from environmental impacts. The wide range of polyolefin cable end caps is available to suit the commonly used cable heat shrink tubes like PVC, PILC, XLPE, or other. The major benefit is that the heat-melt adhesive lining seals the irregular cable tube ends.

3. Heat Shrink Moulded Shapes: The leading brands like Gala offer ever-expanding range of hot shrink molded shapes including anti-tracking breakout, rain sheds used to enhance used to increase the surface creeping distance of outdoor cores termination, semi-conductive cable breakout-anode cap, straight boot and right angle boot used to insulate the cable bushes in termination box, etc.

4. Heat Shrink Coupler: These are being used at a wide scale to link the corrugated HDPE pipes. Heat melt lining of adhesive provides 100% insulation as per IP 68 (Ingress Protection). These are preferred because of being more cost-effective and easy to use compared to the traditional snap-fit coupler or butt welding.

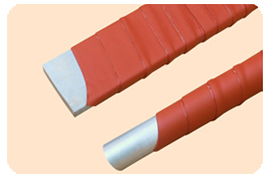

5. Heat Shrink Tape: It is a heat melted polyolefin film with adhesive coating. These are widely used for electrical cable repairing and wire insulation. Easy to use, waterproof and tough to stress, the heat shrink tape gives a versatile solution to insulate and protect medium voltage range bus- bar connections as per global standards.

Concluding Note:

As the heat shrink technology is making advancements, the top manufacturers of heat shrink products in India are expanding their product range. In addition to the above five accessories, you can consider busbar tubes, thin wall tubes, oil barrier sleeves, bus bar insulation shrouds, bus bar end caps, and many others also to make your electrical installation safe from hazards as well as protected to avoid any accident. The online experienced consultants of the leading brands of heat shrink products guide the users to have the best feasible and recommend accessories to make the installations safe and protected.