Heat shrink tubing is a singular way of providing protection to your electric cables. This is a polyolefin material which is cross linked and fitted around the electric cables with the help of a hot air gun. It is a must have item in several applications of the commercial, residential, military and industrial sector.

Heat Shrink Ratios- Important Factor while Making a Choice

Heat shrink tubes shrink in differing ratios. It is therefore essential to choose the one that is best suitable for your application. There are three kinds of shrink ratios of this tubing and they are:

- 2:1 tubing- The shrinkage factor is 50%. This means that the heat shrink tubing reduces to ½ the size of the original diameter.

- 3:1 tubing- The shrinkage factor is 1/3rd and this means the tubing shrinks to 1/3rd of the original diameter size on heating.

- 4:1 tubing – Here the shrinkage ratio is the maximum as the tubing shrivels to 1/4th the size of the original diameter size.

The shrinkage ratios become important considerations as the wire or cable can break if the tubing becomes too tight and if the tubing remains loose then it will not hold the wire or cable. The relevant supplier or manufacturer can guide you best in this regard.

Other Factors

There are a couple of other factors that have to be borne in mind before deciding the quantity of the tubing required. The length of the cable or wire along with that of the connector has to be ascertained if it is going to be a single one. In addition, the width also should be measured. In case there are multiple wires then they have to be bunched together very well with the help of an electrical tape and their length and widths have to be ascertained. Some allowance has to be provided for the shrinking percentages. In this context the shrink ratios are decisive factors and therefore understanding the ratios proves very helpful.

Varied Types of Tubing

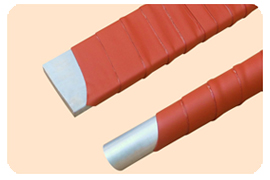

This form of tubing acts as a protective cover to the cables and wires against moisture and shocks. There are different varieties of this tubing such as single wall or dual wall tubing, specialty tubing, heavy duty tubing, vehicle tubing, medical grade tubing and heat shrink joints.

The single wall tubing is again bifurcated into thick, medium and thin walls. The dual wall tubing has an inner wall which contains an encapsulate or an adhesive which gives additional protection to the connections and components from corrosion. The adhesive gets bonded easily with metal, rubber or other substrates. Another classification that is available is their categorization into the rigid, semi-rigid and flexible varieties. The right one is selected depending upon the requirements of the application.

Related Products

All the applications in the power systems require the items to belong to the heat shrink variety. Besides the heat shrink tubes, other products that are commonly used in this sector are heat shrinkable terminations and joints, heat shrink tape, heat shrink sleeve, heat shrink coupler, stress control cap and many more. All these products should be sourced from a reliable manufacturer as only then they will serve the purpose for which they are intended.