With dependence on electricity increasing with each passing day, demands of cables are on the rise as well. The cables need to be joined with one another so that the flow of electricity takes place smoothly from the source of electricity to the end point. Various kinds of cable jointing systems have been developed and implemented which help in maintaining continuity of the cables when they need to be extended to long lengths. To create the best cable joints, various kinds of accessories are needed and some most important ones among them include heat shrink tape, PVC caps, sealing and cable caps etc. In case the joints are loose, there will be electricity leakage and accidents might take place.

Differentiating cable joints depending on various factors

If you thought that cable joints are simple things, you are highly mistaken. They are available in many standard varieties in the market. Apart from these, there are customized cable joints available as well to cater to specific client needs. The cable jointing system has to be selected keeping many things in mind. Some of the most important aspects to consider include:

- Insulation – Compatibility between the cable insulation and the joint is important. All cable terminations will not be suitable for all kinds of cables and will depend upon the function carried out by each cable. There are different procedures and materials for different kinds of insulations. Molded type insulation and use of heat shrink tapes are the two most commonly used kinds of insulation.

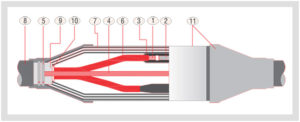

- Structure of the joints – The way in which cables are to be connected will decide the structure of the joint. For cables that are to be connected at a single point, straight through joint is the most preferred way. Branch connectors should be used if the cable has to branch off from the main line. These connectors are also used when two or more cables need to be connected at one single point.

- Voltage – Voltage levels of cables plays an important part in deciding what kinds of cable joints are to be used. There are low, high and medium voltage levels and the cable joints should be chosen accordingly. If the voltage capacity of the joint is lesser than the cable, there will be no functioning as there will be immense pressure of the high electric current. Using 36 Kv cable joints is one of the preferred choices of people.

- Cores – Insulated cores vary from one cable to another. Single and multiple insulated cores are the most common ones. One thing has to be kept in mind in this regard. The numbers of cables that need to be joined and the numbers of cores that the cable joint has should be the same.

There are many companies which deal with cable management products. As mentioned previously, there are different kinds of accessories required for cable management and cables and joints form integral parts of the same. While buying the products, make sure that you purchase them from a reputed and trusted seller – either online or offline.