Heat shrink tubes as the name suggests are specific tubing that is supposed to shrink on the application it is meant for after being exposed to heat. It has a wide range of uses in the electrical and electronic industry.

Basic Uses of Heat Shrink

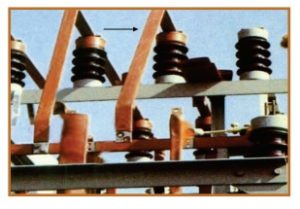

Heat shrink tubing is fundamentally used for insulating wires from extreme heat and in that sense it functions as excellent insulation covers. It also performs several other important functions like protecting and sealing cable joint wiring from environmental factors like dust and moisture or preventing it from being scratched by dirt, general exposure or strong winds. Besides being of great use for repairing marred cables and wires the tubing enables bunches of wires to be harnessed together into specific groups.

Material Used in its Production

The material that is basically used in the production of this type of tubing is thermoplastic material with polyvinyl chloride and polyolefin being the two most common choices. Normally, an addition of some extra materials is done during the production process to give the heat tube supplementary features like weather-proofing etc.

The production process is different for this form of tubing as it incorporates a procedure which enables the tubing to expand. The procedure is known as cross-linking and this exposes the mix’s polymer content to radiation. Because of this, the atoms in the polymers form covalent bonds. This enables the tube to maintain its enlarged form up to the application of heat. When the tube is heated to the required temperature it will go back to its original diameter and form. This is dependent on what is termed as its heat shrink ratio which is different for each tube.

Common Applications

There are several applications to the heat shrink tubing ranging from preventive maintenance to production of electrical circuits. It proves highly useful for relieving stress of electrical wiring that is often generated by tightening and twisting wires at or adjoining the connectors. Twisting actions can impair the wires inside the cable and also damage the insulation around. Shrinkable tube is of great use for adding extra insulation or repairing and re-enclosing the distressed wiring. Terminals and connectors that are exposed to environmental elements like water etc can be provided weatherproofing by the use of this tubing. Splicing wires together can be easily done with these heat tubes.

Another commonly found application is organizing bundles of wires; differently colored tubing can be used for identifying circuits with their job roles or cables with their connection usage.

Selection Factors

There are several factors to be considered when it comes to selecting heat shrink tubes. Voltage, sizing requirements, temperature, environment ratings and the sleeve diameter are some of them. The sleeve diameter is an important one as the tube has to be sufficiently large to be enclosed over the application without compromising it in any way. Besides these, the heat shrink ratio is equally vital to be considered as that will ensure a snug fit over the application.

However, the most important of all is to buy the heat shrink products from a reputed manufacturer!