Heat shrink tubing is always seen wherever there are wires and cables and work great to provide protection and offer cosmetic augmentation to the application. Though such an indispensable and commonly used product there are very few who know the history behind it.

The tubing came into existence thanks to the efforts of Paul Cook who worked as a chemical engineer for Raychem Corporation. Though this organization is the pioneer in production of heat shrink products today there are several manufacturers who are into it. The tubing is made from a variety of thermoplastics like polyvinyl chloride, polyolefin, fluorinated ethylene propylene and polytetrafluoroethylene. There are special kind of heat shrink that are lined with adhesive which gives better bonding between the tubing and the underlying connectors and cables. The resulting seals are water resistant. Addition of thick film of conductive polymer to the tubing enables an electrical connection to be formed between two or plus conductive objects which are to be joined by the tubing. This eliminates the requirement of soldering.

One of the typicality of these products whether it is a heat shrink coupler or heat shrink sleeve is that they shrink on providing heat. This aspect distinguishes it from all the other plastics and it occurs due to the process of cross-linking. Certain plastics can be altered with respect to their molecular structure such that they do not flow or melt irrespective of the temperature they are exposed to. The process which is termed as ‘cross-linking’ also endows the polymers with plastic memory. This enables them to come back to their original dimensions from their stretched and expanded shape on application of heat. The shrinkage differs depending upon the type of tubing. Varied shrink ratios ranging from 2:1 to say 6:1 are available in the market to cater to the wide requirements of the customers.

Heat shrink sleeve is an anti-corrosive coating applied to pipelines as a wraparound sleeve on to the cutback at the field joint while the pipeline is being constructed. The sleeve has an adhesive lining which ensures a strong bonding between the sleeve and the cutback as well as the mainline coating applied by the factory. Besides acting as anti-corrosive material, the sleeve safeguards the pipelines against soil stress and abrasion once they are placed below the ground. Different types of adhesives are used depending upon the environment of the pipeline.

Heat shrink coupler is a kind of tubing that is used to join corrugated HDPE pipes. The pipes are in turn used in several industries like construction, sewer and drainage, mining or for protecting underground cables. This jointing option is cost-effective in comparison to the traditional Butt welding option. The GHW tubes are highly successful in protecting and effectively sealing below-the-ground straight through 36 KV cable joints.

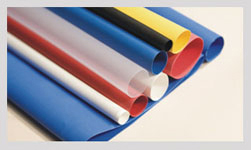

All heat shrink products are available in varied sizes, shapes and colours and you can choose the one that is best suited to your requirements. Customization is also offered by several manufacturers. Buy your requirements from reputed manufacturers or dealers in order to ensure that your application functions for long times to come.