Have you anytime encountered an accident while any electrical work was under progress? Chances of such incidents are not rare if adequate precautions are not taken. An apprentice electrician getting fatally injured due to touching live bus bars that have remained exposed in any industrial setting is a very simple example of such an occurrence.

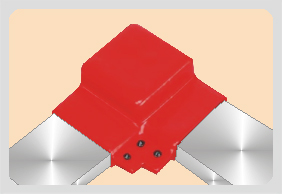

You may ask, what are bus bars? Bus bars are a vital component of any power distribution system. It comprises of a dense copper or aluminum strip that facilitates the conducting of electricity in a switchboard, substation or a power distribution board. They prove to be a very critical item when it comes to the transmission of large load currents or distribution of current to varied devices. However, they have to be used with appropriate care in any electrical setting. Several protective shields are available in such a context like thebus bar connection shrouds, bus bar boots etc. These are plastic moulded and very flexible and act as insulating coverings to the bus bar connections and switchgear. Made from polyvinylchloride material they can withstand very high operating temperatures on a continuous basis. Bus bar connection shrouds are used for coating various conductors which enables the flow of electrical current to be halted in case of emergencies and prevent the incidence of short circuits, shocks or fires. Bus bar heat shrink sleeve also acts as a protective insulation covering. All heat shrink products including heat shrink tubes are indispensable when it comes to any electrical work.

The attributes of bus bar devices enhance safety of lives and equipment in any electrical setting and prevent the occurrence of voltage linked accidents.Some of their advantageous features include sheer dielectric strength, ease of installation and removal, UV rays and ozone resistance, superior electrical and thermal features and low tooling costs. Customized designs are available to suit customer requirements.

In the above example, no accident would have occurred if the live bus bar was covered with a bus bar end cap. In any industrial setting the safety of the workers is of paramount importance and no compromise can be made in that regard. Especially the workers who handle high voltage switchgear have to adhere to all measures that prevent occurrence of electrical hazards. Installation of bus bar boots ensures that adequate distance exists from energized components.

The material used for the manufacture of bus bars is aluminum, copper or cuponal depending upon the needs of the application. Aluminum is lightweight and hence aluminum bus bars are seen more in the rail and aerospace industry. However, it requires more care during its installation. Cuponal goes into the making of transformers and the marine industry.

It is always better to obtain all your electrical components from a reputable manufacturer. Besides obtaining products at cost effective prices you are always assured of its quality. Additional services like assembly of earth bars and insulators, tailor-made sleeving, electro plating in zinc and tin finishes are offered by a majority of them. So, always choose a well-known manufacturer for stocking all your bus bar requirements to ensure a long life to your product.