Busbar boots and busbar sleeve are two important components of power cable accessories and used mainly in the industrial electric sector. For that matter, any setting which requires handling of high voltage switchgear needs the protection offered by these two pieces of equipment.

Need for Workplace Safety

Every industrial setting is susceptible to risks of electrical hazards and reducing their incidence to the minimum is the responsibility of every employer and employee. The major reasons for the occurrence of these accidents include unsafe equipment, wrong installation, unsafe work habits and unsafe environment. Adopting safe work habits, use of guarding, plastic coatings, insulation, electrical protective equipment helps in preventing their occurrence.

Use of Insulating Devices

Several insulators are used to coat conductors like metals and others so that adequate protection is offered to workers handling the relevant devices. Mica, glass, plastic coating, rubber, busbar insulation boots are to name a few of them which ensure the stopping or reducing of the electrical current flow when the need arises. This helps in preventing fires, shocks and short circuits. However, if the insulation has to be effective then it has to be compatible with the voltage levels in use and temperature conditions in addition to environmental aspects like oil, moisture and gasoline or any other factor.

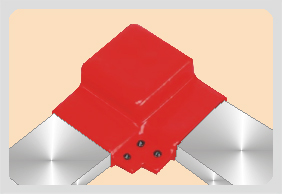

Brief on Bus Bar Boots & Sleeve

Bus bar boots are protective coatings that offer insulation to busbars and switchgear. Manufactured from polyvinyl chloride they are devised for high voltage electrical applications. Bus bar sleeve is a heat shrink tube formulated for insulating busbar systems up to 36KV so as to prevent incidences of accidental flashover. The sleeves are produced from top-rated non-tracking cross-linked polyolefin substance. Both these items contribute a great deal towards lowering the incidence of electrical accidents in the industrial workplace.

Safe Work Habits

All employees exposed to high voltage equipment need to use protective equipment for themselves in the course of their working. Insulating hoods, gloves, matting, sleeves, blankets, industrial safeguard helmets are just some of the items that prove useful here. Each one of them goes towards reducing the danger of electrical accidents.

Adequate Training

Employees have to be provided adequate training on the usage of safety measures while on their jobs. Some fundamental precautions they need to remember include de-energizing equipment, using lockout and tag systems to confirm that they remain de-energized, resorting to insulating protective devices and using bus bar boots to retain sufficient distance from parts that are energized.

Delegation of Responsibility

Every industrial setting needs to have a reliable health and safety program in place in order to minimize the occurrence of electrical hazards. A person who is knowledgeable on sound electrical work habits, relevant OSHA standards for installing and evaluating performance of the equipment has to be appointed in charge of the program.

Summarizing

Workers who don protective gear while on their job remain safe and productive. It is therefore essential that they are equipped with all the right and necessary equipment when being exposed to high voltage switchgear.