The technological advances in the modern world have brought a lot of products to make our lives safer against the odds of electrical applications. The heat shrink technology is one of the most important technologies that are still a secret for the vast community of electricity users. The technology is being used widely to make electrical installations safe for the engineers and post-installation users. As the global acceptance of insulation enhancement products is increasing, leading brands like Galathermo are also expanding its products range.

What Is Heat Shrink Technology For Electrical Insulation?

Heat-shrink tubes are shrinkable silicon rubber tubes. These are used to securely insulate the wires/cables, joints, terminals and connections in electrical installations and other applications including the manufacturing of electrical equipment. Invented by Paul Cook in the 1950s, heat-shrink tubes shrink radially when heated. Heat shrink insulation enhancement products, made of Polyolefin, provide long-term protection from moisture, abrasion, cutting, usage impacts, abrasion, scuffing etc. To facilitate the engineers, heat shrink insulation products are made available in a range of color-coding. Polyolefin heat shrink tubes can be used in a temperature range of 125°C–135°C. PVC is considered comparatively a low-cost alternative of Polyolefin but its temperature range is about 100°C.

The Range of Insulation Enhancement Products for Electrical Installations:

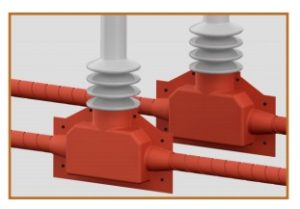

The electrical bus bars, connections, conductors, and joints without insulation always have high risk of accidents because of short circuits, flash overs or earthling etc. Birds, animals and humans often come into contact with un-insulated parts of electrical installations. The range of heat-shrink insulation enhancement products to secure vulnerable electrical components is expanding continuously, even with the facility for customized solutions for bulk requirement:

- High voltage bus-bar tapes:

- Bus connection insulating covers

- Reusable flashover & birds protection cover

- HV insulator protection cover

- Flexible insulation boot

- Bus-bar insulation shroud

- Insulation sleeves

- Reusable overhead line insulation cover

Why You Should Adopt Heat Shrink Technology To Make Electrical Installation Safe:

Supply interruptions increase maintenance costs as well as lower the service standard and customer satisfaction. The faults in substation are expensive and time taking; most of times, you need to cut off power supply of a large area. Many faults, occurred just because of improper insulation, harm the equipments; and, the replacement is costly as well as hectic because of the additional high cost and complicated process. The heat shrink electrical insulation products are available in a wide range to make the overhead lines, substations, distribution centers, transmission lines accident protected and long-lasting. To select the best quality electrical insulation products compare the specifications like:

- Volume resistivity

- Dielectric strength

- Dielectric constant

- Tensile strength

- Thermal endurance

- Flammability

- Water absorption

- Ultimate elongation etc

Over the years, Galathermo has become a favorite brand of engineers because of offering premium quality heat shrink products with cost advantage and more flexibility to choose the electrical insulation products for a particular application. The company provides assistance also to help you choose and buy the reasonably best products to make the indoor and outdoor electrical installations safe.