Cold shrink and heat shrink tubes look identical when you see them at the surface but the internal characteristics are too different. Cold shrink and heat shrink tubes have different insulation mechanisms because of different properties; therefore, these are used in different applications. The tubing is used in an increasing range of applications in different business sectors; the usage is not limited just to insulation, splicing, environmental sealing, terminating, etc. Heat shrink and cold shrink tubes and accessories are more cost-effective to be used in harsh environments than using other tubing types. A thin separation line exists between heat shrink and cold shrink tubes; the major difference we see in the way of application of both.

Heat shrink tubes come pre-stretched. Heat shrink tubes need a heat source for tight-fit installation and can’t be installed without a heat gun. On being heated, the polyolefin heat shrink cable tubing shrinks to its original size to create a tight-fit seal on the cable joint. The polyolefin material used in heat shrink tubes is highly resistant to chemicals, gases, and water because it becomes extremely ridged after heating. Heat shrink tubes are preferred because of getting mechanical protection also. Heat shrinks tubes are finding increasing applications in industrial and commercial installations in low-temperature areas where the presence of chemical gases is high in the environment. The prominent heat shrink tubes manufacturers supply and export different types of heat shrink tubes made of-

- Polyolefin

- PTFE (Polytetrafluoroethylene)

- FEP (Fluorinated ethylene propylene)

- PVDF (Polyvinylidene fluoride)

- Elastomeric

- Silicone

Cold shrink tubes are made of silicone rubber. These are made available in stretched form with a removable plastic core that facilitates for easy mobility. After the placement of cold shrink tubes over the cable joints or cable terminations, the inner cover is pulled out allowing the tube to contract up to its pre-stretched size and to deliver a long-term effective sealing of the joint. Cold shrink tubes are a better option to protect XLPE cable insulation against overheating. Cold shrink tubes also benefit the users because you don’t need an ideal time for cooling before energizing the cables. Cold shrink tubes create a static and stable seal over the joints that don’t expand or contract. Typical applications of cold shrink tubes include – Sub-Bottom Profiling, Sidescan Sonars, underwater camera systems, data telemetry systems, digital video recorders, electric survey winches, marine pumps, underwater trenching machines, etc.

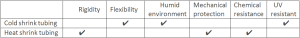

Heat Shrink Vs Cold Shrink at a Glance:

How To Buy The Best Suitable Cable Insulation Tubes:

Now you are well familiar with which type of cable Insulation shrink tube is good for you in a particular environment. Your next concern would be to buy the cable Insulation shrink tube in a hassle-free manner assuring for the robust protection to justify your decision. Here, I would like to recommend you Gala Thermo to buy heat shrink tubes with complete assistance. To buy cold shrink cable insulation tubes, you can approach the top manufacturers like YamunaPower, Thorne & Derrick, Shripat Tech, etc.