Heat shrink tube, also known as heat shrink sleeve, is a specially manufactured polyolefin casing widely used to provide tough insulation and corrosion protection to electrical cables, solder joints, components in electrical installation and mechanical components like pipes. Heat-shrink tubes, a type of extruded plastic tubes, when heated to a certain degree of temperature for a recommended period, reduce their size to get fit to particular application.

Although heat-shrink tubes are being used since decades yet many electrical engineers and technicians are refrained from the time-tested benefits of using heat-shrink tubes to secure their electrical and mechanical installations. Despite knowing the convincing benefits of using heat-shrink tubes, the numbers of electrical engineers and technicians avoid these small cost heat-shrink tubes insulating accessories just because of not knowing the selection of right size of heat-shrink sleeve for a particular wire size. Here I detail the heat-shrink tube terminology and selection process to help you choose the accurate heat-shrink sleeve size for a particular wire size.

Terminology For Heat-Shrink Tube Selection

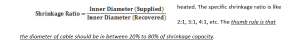

What Is The Shrinkage Ratio? Heat-shrink tubes are available in expanded size that shrink when

Inner Diameter: There are two inner diameters- ‘Inner Diameter’ at supply time and ‘Inner Diameter’ after shrink.

Recovered Wall Thickness: The wall thickness also changes at recovery after heating. You should focus on recovery stage wall thickness while considering the particular application and environment.

How To Choose The Perfect Size Of Heat-Shrink Tube

The top manufacturers and reputed brands like Gala Thermo offer a wide range of heat-shrink tubes to facilitate its clients. The size of the object to be insulated is the base to determine the inner diameter, length, and shrinkage ratio of heat-shrink tube. The other key aspects that you should explore while buying heat-shrink tubes first time are – tubing material, operating temperature, shrinkage temperature, features, suitability to environment.

The most preferred shrink ratio is 2:1 or 3:1. It means, heat-shrink tube is expended 2 or 3 times to its original size. If you expect more size variation of object to be insulated, you should prefer larger shrink ratio. Here, you should keep in mind that there may be 10% of longitudinal change also.

The wall thickness is mentioned in mm or inches. Tubing’s technical data gives you complete information about the wall thickness. The heat-shrink tubes are available in single, double and heavy wall structures. Medium and heavy wall heat-shrink tubes are suitable for the cables up to 36KV. The single or thin wall structured heat shrink sleeves are good up to 3.3 kV electrical cables and components.

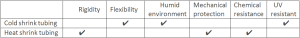

If you are buying the heat-shrink tubes to be used in industrial environment, you should also focus on resistance to weathering, chemical, solvents, UV rays, fungus etc. The other prominent properties, important for informed decision making, are tensile strength (as per ASTM-D-638), ultimate elongation (as per ASTM-D-638), and water absorption (as per ASTM-D-570), etc.

Pro-Tip

To be sure of choosing the quality best heat-shrink tube for the particular cable wire or component, you should also focus on quality standards. The top heat-shrink tube manufacturers and suppliers confirm the quality standards as RoHS Compliance, IEC 60684-3-247, IP 68, etc.