Ever since electricity cables came to be used, the question of joining them also arose at the same time. This led to the existence of the cable jointing system which maintains the continuity of the cables when they are needed in long lengths. Among the several cable accessories available in the market such as the cable end sealing caps, PVC caps, heat shrink tape, etc it is the cable joints by which electricity power cables are connected to each other.

Factors that Differentiate Cable Joints

There are many standard varieties of these available in the market, however; manufacturers also provide custom made joints to suit the specific requirements of certain businesses. An appropriate selection of the cable jointing system has to be made depending upon the operation parameters, site conditions, voltage applications etc. Following are certain factors that influence the selection of these joints:

Voltage: Cable joints have to be selected based on the voltage levels of the cables. Accordingly, they can be differentiated into high, medium and low voltage levels; so, if you have a joint whose voltage capacity is less than that of the cable then it will not work due to the pressure of the high electrical current.

Insulation: There has to be compatibility of the joint and the cable insulation which differs depending upon the purpose for which the cable has to be used. The insulation of the jointed cables thereafter has to be done right. For ensuring proper insulation, you can choose between several procedures such as cold or heat shrinkable insulation which involves the use of heat shrink tape or the molded type of insulation.

Cores: A cable can either have multiple or single insulated cores. In this regard, the number of cores possessed by the cable joint and the cables to be joined has to be the same.

Structure: Structure of the joint will depend upon how the cables are to be connected. If two power cables have to be connected at one point then the straight through joint is most suitable. However, if the cable has to branch off from the main line or more than two cables have to be connected at a single point then the more sophisticated branch connectors can be used.

Types of Cable Joints

Basically, four types of standardized cable joints are available and each has a different mechanical arrangement and is used for different applications. However, custom made joints are also made by manufacturers to fulfill the unique needs of certain customers.

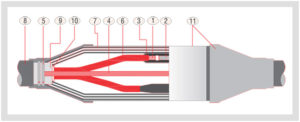

Straight through joints: This is the most commonly used joint and helps in extending the electrical cable pieces. These are suitable for outdoor, indoor, underground and submerged cable jointing.

Pot End joint: These joints are used at the ends of cables having live voltage running through them. Normally, in every cable,the sealing of all cores is done separately using heat shrink cable end sealing caps. Earth fault protection is offered through a screen bandage and the whole thing is covered with a bulky enclosure of heat shrink cap.

‘Y’ or ‘T’ branch joint: This is used to connect polymeric, non-shielded, low-voltage cables with 1 to 5 cores. These are suitable for outdoor, indoor, underground and submerged cable jointing.