Pipeline / Corrosion Protection Products

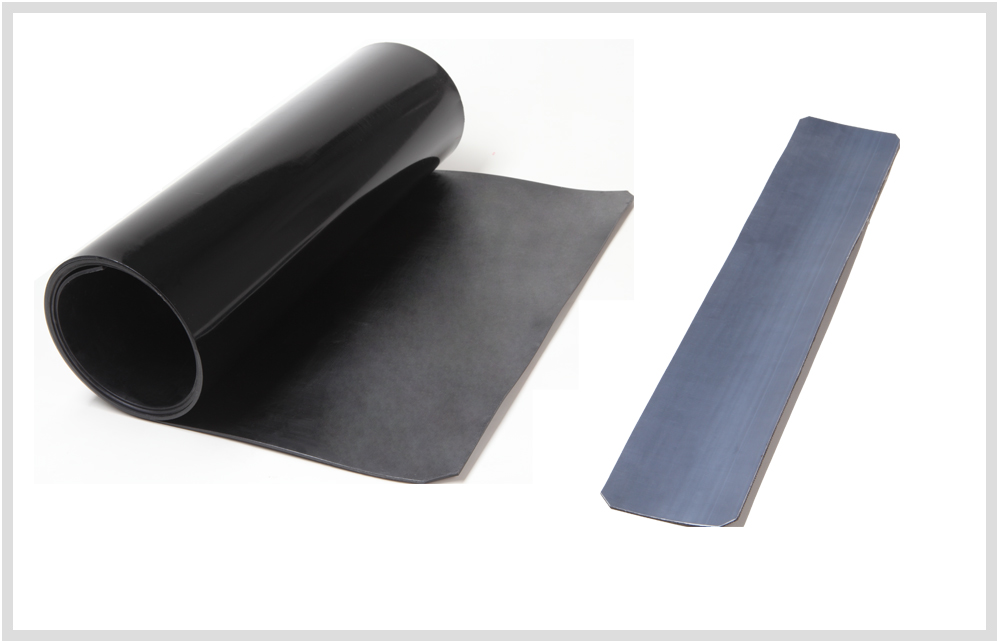

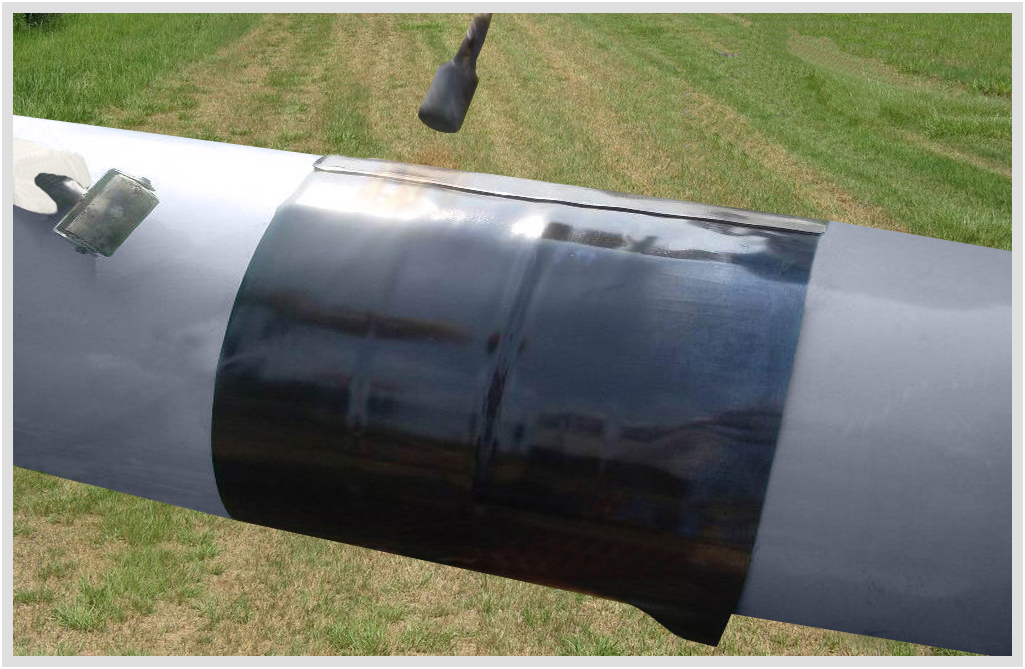

Three Layer Corrosion Protection Sleeve

Heat Shrink Three Layer Corrosion Protection Sleeve is designed to protect the weld joint of buried or exposed steel pipelines and insulated pipeline. This sleeves are manufactured from high quality cross linked polyethylene material. Hot melt adhesive provides excellent adhesion with the surface of steel pipeline, PE coating. Meanwhile it forms a continuous and firm anti-corrosive system with the surface of the pipeline.

Features / Benefits:

- Strong adaptive capacity to environment

- Good resistance to mechanical damage

- It has good resistance to liquid pressure and bacterium, mildew, cathode protection current of pipelines

- Other chemical corrosion caused by liquids and solvents

- Prevents the coat separation caused by UV light

All dimensions are in mm

| Selection Chart | ||||

|---|---|---|---|---|

| Gala Code | Heat Shrink Sleeve | Closure Patch | ||

| Length | Width | Length | Width | |

| GTWS Ø 159 x 500 | 620 | 500 | 100 | 500 |

| GTWS Ø 219 x 500 | 830 | 500 | 100 | 500 |

| GTWS Ø 273 x 500 | 1000 | 500 | 100 | 500 |

| GTWS Ø 325 x 500 | 1200 | 500 | 120 | 500 |

| GTWS Ø 377 x 500 | 1370 | 500 | 120 | 500 |

| GTWS Ø 406 x 500 | 1500 | 500 | 150 | 500 |

| GTWS Ø 426 x 500 | 1560 | 500 | 150 | 500 |

| GTWS Ø 457 x 500 | 1660 | 500 | 150 | 500 |

| GTWS Ø 508 x 500 | 1840 | 500 | 170 | 500 |

| GTWS Ø 529 x 500 | 1900 | 500 | 170 | 500 |

| GTWS Ø 610 x 500 | 2160 | 500 | 170 | 500 |

| GTWS Ø 711 x 500 | 2480 | 500 | 170 | 500 |

| GTWS Ø 720 x 500 | 2500 | 500 | 170 | 500 |

| GTWS Ø 813 x 500 | 2800 | 500 | 170 | 500 |

| GTWS Ø 1016 x 500 | 3430 | 500 | 200 | 500 |

Diameter in Selection Chart refers to OD of pipelines

| Technical Specification | ||

|---|---|---|

| Properties | Value | Standard |

| Sleeve and Closure Patch | ||

| Tensile Strength | 22 N/mm2 (Mpa) | ASTM D638 |

| Ultimate Elongation | 550 % | ASTM D638 |

| Impact Resistance | >15J | ASTM G14 |

| Hardness | 50 ±5 Shore D | ASTM D2240 |

| Water absorption | 0.5 % | ASTM D570 |

| Corrosion Protection against | ||

| Chemicals after 24 hrs. | Elongation | ASTM D2671 |

| immersion in 10% HCL, | 100 % | |

| 10% NaOH, 10% NaCl | 97%, 98% | |

| Abrasion Resistance | 30 mg | ASTM D1044 |

| Cathodic Disbondment | 3 rad | ISO 21809-3 |

| Thermal Ageing | (150° C for 504 hrs) | ASTM D2671 |

| Tensile Strength | 21 N/mm (Mpa) | ASTM D638 |

| Ultimate Elongation | 575 % | ASTM D638 |

| Low Temperature Flexibility (-15° C for 4 hrs.) |

No Cracking | ASTM D2671 |

| Dielectric Strength | 36 MV/m. | ASTM D149 |

| Volume Resistivity | 1 x 1013 Ohm.cm | ASTM D257 |

| Hot Melt Adhesive | ||

| Softening Point | 95° C | ASTM E28 |

| Peel Strength | ASTM D2671 | |

| PE/Steel (25° C/50° C) | 100 N/cm / 30 N/cm | |

| PE/FBE(25° C/50° C) | 120 N/cm / 35 N/cm | |

| PE/PE(25° C/50° C) | 110 N/cm / 30 N/cm | |

Products

Heat Shrinkable Moulded Shapes

Heat Shrink Tubes / Heat Shrink Sleeves

- Advantages Of Heat shrink Tubing

- Thin Wall Tubes

- GDW : Dual Wall Tubing

- Medium/Heavy Wall Tubes-Commercial

- Heat Shrink Co-extruded Tubing Premium Quality

- Red Insulation Tubes

- Non Tracking Tubes

- Busbar Sleeves

- Stress Control Tube

- Integrated Stress Control Tube-GVOT Tube

- Heat Shrink Double Layer Tube-GDTL Tube

- High Shrink Ratio Heat Shrink Tube

Switchgear Insulation Products

- Barrier Board Sheet

- End Sealing Kit for Extensible RMU/GIS Bushing

- Heat Shrink Bus Bar Sleeve

- Bus Bar Insulating Shrouds

- Bus Bar Insulating Shrouds Polyolefin

- Bus Bar End Caps

- Thin wall tube wire marking

- Heat Shrink Tape (Bustape)

- Insulation for Circuit Breakers

- Busbar Sleeve for 66 kV

- Bushing Boot

- Non Shrinkable High Voltage Tape

- Heat Shrinkable Gland