Heat Shrinkable Moulded Shapes

Anti-Tracking Breakout - INSOLCORE Non Tracking

- Insulcore - Non Tracking Cable Breakout provide permanent evironmental seal to the crutch of 3 core PVR PILC cable rate upto 36KV.

- Manufactured from high quality non tracking cross linked polyolefin material that offers exceptional insulation and long term service reliability.

- The breakouts are intenally coated with water resistant mastic.

- Excellent weather / UV resistance

- Good resistance to chemical, solvent, corrosion and fungus.

SELECTION CHART

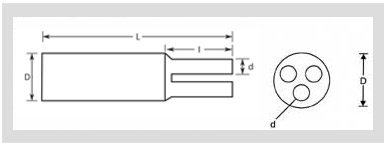

All dimensions are in mm

- Code

- No. of Core

- D

- d

- L

- l

- Tb

- Tc

- s

- f

- s

- f

- s

- f

- s

- F

- min

- max

- min.

- max.

- min.

- max.

- min

- max

- +10%

- +10%

- GAB-0820

- 3

- 60

- 20

- 25

- 8

- 160

- 188

- 45

- 62

- 3.7

- 2.8

- GAB-0820 A

- 3

- 70

- 20

- 27

- 8

- 155

- 188

- 40

- 62

- 3.7

- 2.8

- GAB-1330

- 3

- 80

- 30

- 39

- 13

- 185

- 215

- 60

- 75

- 3.9

- 3.1

- GAB-1330 A

- 3

- 100

- 30

- 39

- 13

- 185

- 215

- 60

- 75

- 3.9

- 3.1

- GAB 2145

- 3

- 110

- 45

- 55

- 20

- 200

- 230

- 70

- 90

- 4.3

- 3.0

- GAB-2145 A

- 3

- 125

- 45

- 55

- 21

- 190

- 230

- 65

- 90

- 4.3

- 3.0

- GAB-2755

- 3

- 140

- 56

- 68

- 28

- 215

- 250

- 80

- 90

- 4.0

- 3.0

- GAB-2755 A

- 3

- 180

- 56

- 70

- 29

- 210

- 255

- 80

- 90

- 4.0

- 3.0

- GAB-3060

- 3

- 200

- 60

- 70

- 30

- 190

- 225

- 70

- 85

- 4.0

- 3.0

D : Internal Diameter ; s : as supplied ; f : after free recovery ; Tb,Tc : Thickness of body & core

TECHNICAL SPECIFICATION

- PROPERTIES

- VALUE

- STANDARD

- Physical

- Tensile Strength

- 12 N/mm2 (MPA)(min.)

- ASTM D638

- Ultimate Elongation

- 350% (Min.)

- ASTM D638

- Density

- 1.15 + 0.2 gm/cm3

- ASTM D792

- Hardness

- 45 + 10 Shore D

- ASTM D2240

- Water Absorption

- 0.5 % (max.)

- ASTM D570

- Thermal

- Accelerated Ageing

- (120oC for 500 Hrs)

- ASTM D2671

- Tensile Strength

- 11 N/mm2 (Mpa) (min.)

- ASTM D 638

- Ultimate Elongation

- 300%(Min.)

- ASTM D638

- Low temperature Flexibility (-40oC for 4 Hrs.)

- No Cracking

- ASTM D2671

- Heat Shock (250oC for 30 Min.)

- No Cracking or flowing

- ESI 09-11

- Shrink Temperature

- 125oC

- IEC 216

- Continuous Temperature limit

- -40oC to + 110oC

- IEC 216

- Electrical

- Dielectric Strength

- 12 KV/mm. (Min.)

- ASTM D149

- Volume Resistivity

- 1 x 1014 Ohm.cm(min.)

- ASTM D257

- Dielectric Constant

- 5 (Max.)

- ASTM D150

- Resistant to track & erosion

- No tracking,erosion or flame failure upto 3.25 KV for 20 min.

- ASTM D2303

Products

Heat Shrink Tubes / Heat Shrink Sleeves

- Advantages Of Heat shrink Tubing

- Thin Wall Tubes

- GDW : Dual Wall Tubing

- Medium/Heavy Wall Tubes-Commercial

- Heat Shrink Co-extruded Tubing Premium Quality

- Red Insulation Tubes

- Non Tracking Tubes

- Busbar Sleeves

- Stress Control Tube

- Integrated Stress Control Tube-GVOT Tube

- Heat Shrink Double Layer Tube-GDTL Tube

Switchgear Insulation Products

- Barrier Board Sheet

- End Sealing Kit for Extensible RMU/GIS Bushing

- Heat Shrink Bus Bar Sleeve

- Bus Bar Insulating Shrouds

- Bus Bar Insulating Shrouds Polyolefin

- Bus Bar End Caps

- Thin wall tube wire marking

- Heat Shrink Tape (Bustape)

- Insulation for Circuit Breakers

- Busbar Sleeve for 66 kV

- Bushing Boot

- Non Shrinkable High Voltage Tape

- Heat Shrinkable Gland