Heat Shrinkable Tubes/Heat Shrink Sleeves

HEAT SHRINK CO-EXTRUDED TUBING PREMIUM QUALITY

GMWR and GHWR are Heat Shrink Co-extruded premium quality medium wall and heavy wall tubing.

This tubes are used as waterproof sealing in cable termination and joints. It is used for corrosion protection, environmental sealing and mechanical protection of pipes and pipe connections. It is also used for insulating underground & aerial connections in CATV plant, CCTV connections and in control cables splicing joints.

Technical Qualification Report : QR 1014

GENERAL PROPERTIES :

- High shrink ratio.

- Co-extrusion technology.

- Soft & flexible.

- Fast & uniform shrinking.

- High resistant to decay , chemicals, copper corrosion & UV rays.

- Tubing with hot melt adhesive lining provides excellent waterproofing and environmental sealing.

- Standard color Black. Other colors available upon request.

SELECTION CHART

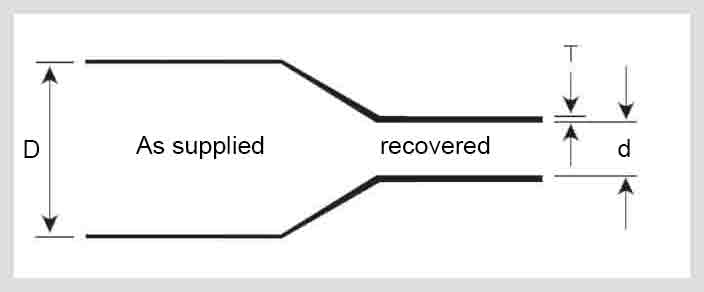

All dimensions are in mm

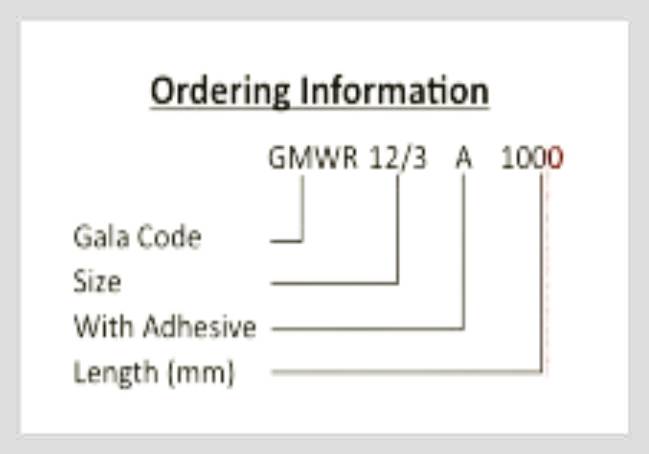

- Code

- D Min (mm)

- d Max (mm)

- T±10 (mm)

- GMWR 12/3

- 12

- 3

- 1.5

- GMWR 12/6

- 12

- 6

- 2.0

- GMWR 27/8

- 27

- 8

- 2.5

- GMWR 33/10

- 33

- 10

- 2.5

- GMWR 40/12

- 40

- 12

- 2.5

- GMWR 50/16

- 50

- 16

- 2.5

- GMWR 63/19

- 63

- 19

- 2.5

- GMWR 72/22

- 72

- 22

- 2.5

- GMWR 92/27

- 92

- 27

- 3.0

- GMWR 130/36

- 130

- 36

- 3.0

- Code

- D Min (mm)

- d Max (mm)

- T±10 (mm)

- GHWR 12/3

- 12

- 3

- 2.2

- GMWR 22/6

- 22

- 6

- 2.5

- GHWR 30/8

- 30

- 8

- 3.0

- GHWR 43/12

- 43

- 12

- 4.0

- GHWR 51/16

- 51

- 16

- 4.0

- GHWR 72/22

- 72

- 22

- 4.0

- GHWR 85/25

- 85

- 25

- 4.0

- GHWR 105/30

- 105

- 30

- 4.0

- GHWR 120/36

- 120

- 36

- 4.0

- GHWR 140/42

- 140

- 42

- 4.2

TECHNICAL SPECIFICATION

| Properties | Value | Standard |

|---|---|---|

| Physical | ||

| Tensile Strength | 9 N/mm2 (MPA)(min.) | ASTM D638 |

| Ultimate Elongation | 300 % (min.) | ASTM D638 |

| Water absorption | 0.15 % (max.) | ASTM D570 |

| Specific Gravity | 1.4 | ASTM D792 |

| Longitudinal Change | -10 % (max.) | ASTM D638 |

| Thermal | ||

| Operating Temp. (Outer Wall) | -55 to +125oC | IEC 216 |

| Heat Shock (250oC for 4 hrs.) | No dripping, cracking or flowing (Outer Wall) | |

| Chemical | ||

| Fungus Resistance | Inert | MIL-1-7444 |

| Copper Corrosion | Good | ASTM D2671B |

| Chemical Resistance | Good | ASTM D2671 |

| Electrical | ||

| Dielectric Strength | 15 KV/mm. (Min.) | ASTM D2671 |

| Dielectric Constant | 3.0 (Max.) | ASTM D150 |

| Volume Resistivity | 1 x 1013 Ohm.cm(min.) | ASTM D257 |

Products

Heat Shrink Tubes / Heat Shrink Sleeves

- Advantages Of Heat shrink Tubing

- Thin Wall Tubes

- GDW : Dual Wall Tubing

- Medium/Heavy Wall Tubes-Commercial

- Heat Shrink Co-extruded Tubing Premium Quality

- Red Insulation Tubes

- Non Tracking Tubes

- Busbar Sleeves

- Stress Control Tube

- Integrated Stress Control Tube-GVOT Tube

- Heat Shrink Double Layer Tube-GDTL Tube

Switchgear Insulation Products

- Barrier Board Sheet

- End Sealing Kit for Extensible RMU/GIS Bushing

- Heat Shrink Bus Bar Sleeve

- Bus Bar Insulating Shrouds

- Bus Bar Insulating Shrouds Polyolefin

- Bus Bar End Caps

- Thin wall tube wire marking

- Heat Shrink Tape (Bustape)

- Insulation for Circuit Breakers

- Busbar Sleeve for 66 kV

- Bushing Boot

- Non Shrinkable High Voltage Tape

- Heat Shrinkable Gland