Thin Wall Tubes

GLC : Thin Wall Tube

GLC is Thin Wall Tube suitable for below applications:

GLC Series :

- Light duty wire harnessing for electrical & electronic applications.

- Provides electrical insulation and protection for in-line components.

- Used as strain relief for electrical wire connection.

- Bus-bar insulation for switchgear.

GENERAL PROPERTIES OF PRODUCT :

- Halogen free

- For Electrical Insulation up to 3.3 kV

- Resistance to chemical, copper corrosion and fungus

- Standard Color: Black

- Shrink ratio 2:1

- UV stabilized

- Meets RoHS Compliance

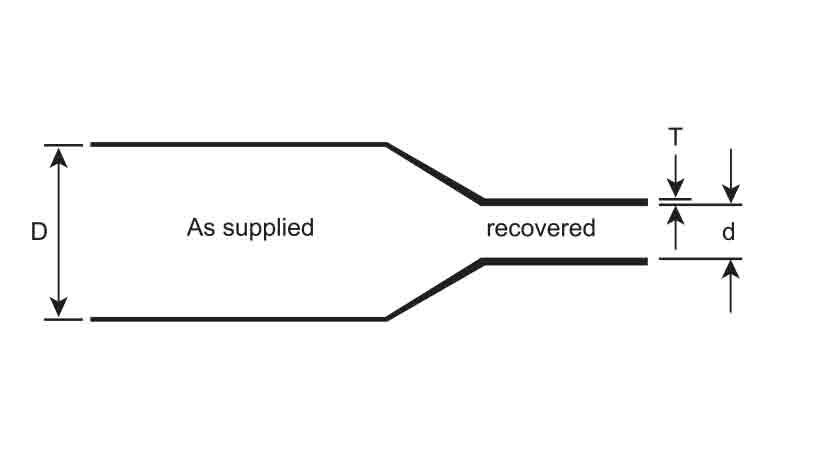

SELECTION CHART

All dimensions are in mm

| Part Number / Size |

Supplied Id (min.) |

Recovered Id (max.) |

Recovered Wall Thick. (±10%) |

Spools Mtr./Spool |

Cut Lengths 1.2Mtr./Box |

|---|---|---|---|---|---|

| GLC 6.0/3.0 | 6.0 mm | 3.0 mm | 0.56 mm | 100 | 200 |

| GLC 7.0/3.5 | 7.0 mm | 3.5 mm | 0.56 mm | 100 | 200 |

| GLC 8.0/4.0 | 8.0 mm | 4.0 mm | 0.56 mm | 100 | 175 |

| GLC 10.0/5.0 | 10.0 mm | 5.0 mm | 0.56 mm | 100 | 150 |

| GLC 12.7/6.35 | 12.7 mm | 6.35 mm | 0.56 mm | 100 | 120 |

| GLC 14.0/7.0 | 14.0 mm | 7.0 mm | 0.69 mm | 100 | 100 |

| GLC 16.0/8.0 | 16.0 mm | 8.0 mm | 0.69 mm | 100 | 100 |

| GLC 18.0/9.0 | 18.0 mm | 9.0 mm | 0.69 mm | 100 | 80 |

| GLC 20.0/10.0 | 20.0 mm | 10.0 mm | 0.78 mm | 100 | 65 |

| GLC 25.0/12.5 | 25.0 mm | 12.5 mm | 0.78 mm | 50 | 40 |

| GLC 30.0/15.0 | 30.0 mm | 15.0 mm | 0.87 mm | 50 | 30 |

| GLC 40.0/20.0 | 40.0 mm | 20.0 mm | 0.97 mm | 50 | 20 |

| GLC 50.0/25.0 | 50.0 mm | 25.0 mm | 0.97 mm | 25 | 15 |

| GLC 60.0/30.0 | 60.0 mm | 30.0 mm | 0.96 mm | 25 | 10 |

| GLC 70.0/35.0 | 70.0 mmm | 35.0 mm | 1.10 mm | 25 | 10 |

| GLC 80.0/40.0 | 80.0 mm | 40.0 mm | 1.27 mm | 25 | 10 |

| GLC 100/50.0 | 100.0 mm | 50.0 mm | 1.17 mm | 25 | 5 |

TECHNICAL DATA

- PROPERTIES

- VALUE

- STANDARD

- Physical

- Tensile Strength

- 10 N/mm2 (Mpa) (min.)

- ASTM D638

- Ultimate Elongation

- 200 % (min)

- ASTM D638

- Water Absorption

- 0.15 % (max.)

- ASTM D570

- Longitudinal Change

- -10% (max.)

- ASTM D638

- Thermal

- Operating Temperature

- -55 to +125oC

- IEC 216

- Low Temperature Flexibility

- No Cracking

- ASTM D2671

- (-55oC for 4 hrs.)

- Electrical

- Dielectric Strength

- >15 kV/mm.

- ASTM D2671

- Di-electric Constant

- 5.0 (max.)

- ASTM D150

- Volume Resistivity

- 1 x 1014 Ohm.cm (min)

- ASTM D257

Products

Heat Shrink Tubes / Heat Shrink Sleeves

- Advantages Of Heat shrink Tubing

- Thin Wall Tubes

- GDW : Dual Wall Tubing

- Medium/Heavy Wall Tubes-Commercial

- Heat Shrink Co-extruded Tubing Premium Quality

- Red Insulation Tubes

- Non Tracking Tubes

- Busbar Sleeves

- Stress Control Tube

- Integrated Stress Control Tube-GVOT Tube

- Heat Shrink Double Layer Tube-GDTL Tube

Switchgear Insulation Products

- Barrier Board Sheet

- End Sealing Kit for Extensible RMU/GIS Bushing

- Heat Shrink Bus Bar Sleeve

- Bus Bar Insulating Shrouds

- Bus Bar Insulating Shrouds Polyolefin

- Bus Bar End Caps

- Thin wall tube wire marking

- Heat Shrink Tape (Bustape)

- Insulation for Circuit Breakers

- Busbar Sleeve for 66 kV

- Bushing Boot

- Non Shrinkable High Voltage Tape

- Heat Shrinkable Gland