Heat Shrink Double Layer Tube-GDTL Tube

Insultube ‐ Double Layer is manufactured by Heat Shrinkable Insulating material and Heat Shrinkable Semi-Conductive material with special technology for good insulation in its inner layer and good semi-conduction in its outer layer; providing reliable shield protection.

This tubes are made from High Quality Cross-linked Polyolefin material with Co-extrusion Technology.

This tube is used in Power Cable Straight Through Joints for insulating and outer-shielding layer up to 36kV. It can also be used to other places wherever insulation and shielding is required.

SELECTION CHART

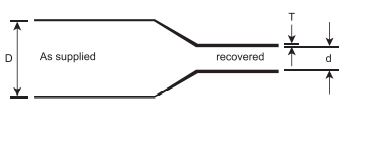

All dimensions are in mm

- Gala Size

- D (Min.)

- d (Max.)

- T (Min.)

- GDLT 30/11

- 30

- 11

- 5.0 ± 0.3

- GDLT 35/13

- 35

- 13

- 5.0 ± 0.3

- GDLT 45/16

- 45

- 16

- 5.0 ± 0.3

- GDLT 55/20

- 55

- 20

- 5.0 ± 0.3

- GDLT 65/27

- 65

- 27

- 5.0 ± 0.3

- GDLT 85/30

- 85

- 30

- 7.5 ± 0.3

- GDLT 100/35

- 100

- 35

- 7.0 ± 0.3

- GDLT 120/45

- 120

- 45

- 7.0 ± 0.4

D,d : Internal Diameter; T : Thickness

TECHNICAL SPECIFICATION

| PROPERTIES | INNER INSULATION LAYER | OUTER SEMI-COND. LAYER | STANDARD |

|---|---|---|---|

| Value | Value | ||

| Physical | |||

| Tensile Strength | 12 Mpa(N/mm2) (min.) | 12 Mpa(N/mm2) (min.) | ASTM D638 |

| Ultimate Elongation | 300% (Min.) | 300% (Min.) | ASTM D638 |

| Longitudinal Change | -10% (Max.) | -10% (Max.) | ASTM D2671 |

| Hardness | 50 ± 3 Shore D | 50 ± 3 Shore D | ASTM D2240 |

| Water absorption | 0.5 % (max.) | 0.5 % (max.) | ASTM D570 |

| Thermal | |||

| Accelerated ageing | ( 120⁰C for 500 Hrs ) | ( 120⁰C for 500 Hrs ) | ASTM D2671 |

| Tensile Strength | 10.5Mpa (N/mm ) (min.) | 10.5Mpa (N/mm ) (min.) | ASTM D638 |

| Ultimate Elongation | 270 % (min.) | 270 % (min.) | ASTM D638 |

| Low Temperature Flexibility | No Cracking | No Cracking | ASTM D2671 |

| -40⁰C for 4 hrs.) | |||

| Heat Shock (250⁰C for 30 min.) | No cracking or flowing | No cracking or flowing | ESI 09-11 |

| Shrink Temperature | 135⁰C | 135⁰C | IEC 216 |

| Continuous Temperature limit | -40 to +100⁰C | -40 to +100⁰C | IEC 216 |

| Electrical | |||

| Dielectric Strength | 20 KV/mm.(min) | N/A | ASTM D149 |

| Volume Resistivity | 1 x 1014 Ohm.cm (min) | 1 x 103 Ohm.cm (min | ASTM D257 |

Features & Benefits:

- Dual wall Conducting / Insulating.

- Excellent Electrical properties.

- Operation Temperature : -40⁰C to 100⁰C

- Minimum Shrink Temperature : 100⁰C.

- Minimum fully Shrink Temperature : 130⁰C

- Standard Color : Black/Red

Products

Heat Shrink Tubes / Heat Shrink Sleeves

- Advantages Of Heat shrink Tubing

- Thin Wall Tubes

- GDW : Dual Wall Tubing

- Medium/Heavy Wall Tubes-Commercial

- Heat Shrink Co-extruded Tubing Premium Quality

- Red Insulation Tubes

- Non Tracking Tubes

- Busbar Sleeves

- Stress Control Tube

- Integrated Stress Control Tube-GVOT Tube

- Heat Shrink Double Layer Tube-GDTL Tube

- High Shrink Ratio Heat Shrink Tube

Switchgear Insulation Products

- Barrier Board Sheet

- End Sealing Kit for Extensible RMU/GIS Bushing

- Heat Shrink Bus Bar Sleeve

- Bus Bar Insulating Shrouds

- Bus Bar Insulating Shrouds Polyolefin

- Bus Bar End Caps

- Thin wall tube wire marking

- Heat Shrink Tape (Bustape)

- Insulation for Circuit Breakers

- Busbar Sleeve for 66 kV

- Bushing Boot

- Non Shrinkable High Voltage Tape

- Heat Shrinkable Gland