Heat Shrink Polyolefin Tube for U-Bolt Coating

Heat Shrink Polyolefin Tube for U-Bolt Coating is suitable for corrosion and mechanical protection between U-Bolts & Pipes.

Pipes running through refineries, chemical plants and offshore platforms are rested on, or secured to, a structural beam support member using U-bolts. Over time the contact area between the un-coated U-bolts and pipe erodes and starts deteriorating the material in the presence of moisture. This excessive corrosion at the pipe support point is the leading cause of process pipe failure and it eventually develops into pinhole leaks.

Features & benefits :

- High resistance to impact & abrasion.

- Smooth, durable and shrunk over the shank of the U-bolt without any wrinkles, thereby helps reduce the risk of cracking the paint film around the pipe as the bolt is torqued down.

- The polyolefin material provides the right combination of hardness and durability to protect the pipe paint but avoids setting up a capillary crevice around the circumference of the pipe.

- Has superior jacket tear resistance & elastomeric characteristics allowing better conformance over irregular contours without splitting.

- Provides mechanical protection and better abrasion resistance in harsh environments, e.g. tube rubbing against sharp objects or in constant friction

- Provides good strain relief.

- High shrink ratio (3:1) can help rationalize the stock requirements and also provides a greater application range.

- After recovery, it provides an excellent outer cover for protection.

- Highly reliable as it is unaffected by heat, ultra-violet rays, vibration, sandblasting or other conditions pertaining to an industrial and marine environment

Market Segment: Electrical, Offshore, Marine, Industrial Oil and Gas Utilities

SELECTION CHART

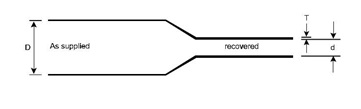

All dimensions in mm

- Code

- D Min.

- d Max.

- T±10%

- (mm)

- (mm)

- (mm)

- GMWR 9/3

- 9

- 3

- 1.5

- GMWR 10/3

- 10

- 3

- 1.5

- GMWR 12/4

- 12

- 4

- 1.65

- GMWR 16/5

- 16

- 5

- 2.0

- GMWR 19/6

- 19

- 6

- 2.0

- GMWR 22/6

- 22

- 6

- 2.0

- GMWR 27/8

- 27

- 8

- 2.75

- GMWR 30/8

- 30

- 8

- 3.0

- GMWR 30/10

- 30

- 10

- 3.0

- GMWR 35/12

- 35

- 12

- 2.5

- GMWR 40/12

- 40

- 12

- 3.0

- GMWR 50/16

- 50

- 16

- 3.0

- Code

- D Min.

- d Max.

- T±10%

- (mm)

- (mm)

- (mm)

- GHWR 12/3

- 12

- 3

- 2.4

- GHWR 19/6

- 19

- 6

- 2.5

- GHWR 22/6

- 22

- 6

- 2.75

- GHWR 27/8

- 27

- 8

- 3.5

- GHWR 30/8

- 30

- 8

- 3.5

- GHWR 30/10

- 30

- 10

- 3.5

- GHWR 35/12

- 35

- 12

- 3.5

- GHWR 40/12

- 40

- 12

- 4.0

- GHWR 50/16

- 50

- 16

- 4.0

TECHNICAL SPECIFICATION

- PROPERTIES

- VALUE

- STANDARD

- Physical

- Tensile Strength

- 12N/mm2 (MPA)(min.)

- ASTM D638

- Ultimate Elongation

- 350% (min.)

- ASTM D638

- Longitudinal Change

- - 10% (max.)

- ASTM D2671

- Water Absorption

- 0.5 % (max.)

- ASTM D570

- Accelerated Ageing

- (120°C for 500 Hrs)

- ASTM D2671

- Tensile Strength

- 12 N/mm2 (Mpa) (min.)

- ASTM D 638

- Ultimate Elongation

- 300 % (min.)

- ASTM D 638

- Heat Shock (250°C for 30 min.)

- No Cracking or flowing

- ESI 09-11

- Continuous Temperature limit

- -40°C to + 110°C

- IEC 216

- Dielectric Strength

- 12 kV/mm. (min.)

- ASTM D149

- Volume Resistivity

- 1 x 1013 Ohm.cm(min.)

- ASTM D257

- Dielectric Constant

- 5 (max.)

- ASTM D150

Technical Qualification Report : QR 1025

Products

Heat Shrink Tubes / Heat Shrink Sleeves

- Advantages Of Heat shrink Tubing

- Thin Wall Tubes

- GDW : Dual Wall Tubing

- Medium/Heavy Wall Tubes-Commercial

- Heat Shrink Co-extruded Tubing Premium Quality

- Red Insulation Tubes

- Non Tracking Tubes

- Busbar Sleeves

- Stress Control Tube

- Integrated Stress Control Tube-GVOT Tube

- Heat Shrink Double Layer Tube-GDTL Tube

- High Shrink Ratio Heat Shrink Tube

Switchgear Insulation Products

- Barrier Board Sheet

- End Sealing Kit for Extensible RMU/GIS Bushing

- Heat Shrink Bus Bar Sleeve

- Bus Bar Insulating Shrouds

- Bus Bar Insulating Shrouds Polyolefin

- Bus Bar End Caps

- Thin wall tube wire marking

- Heat Shrink Tape (Bustape)

- Insulation for Circuit Breakers

- Busbar Sleeve for 66 kV

- Bushing Boot

- Non Shrinkable High Voltage Tape

- Heat Shrinkable Gland