×

Get in Touch

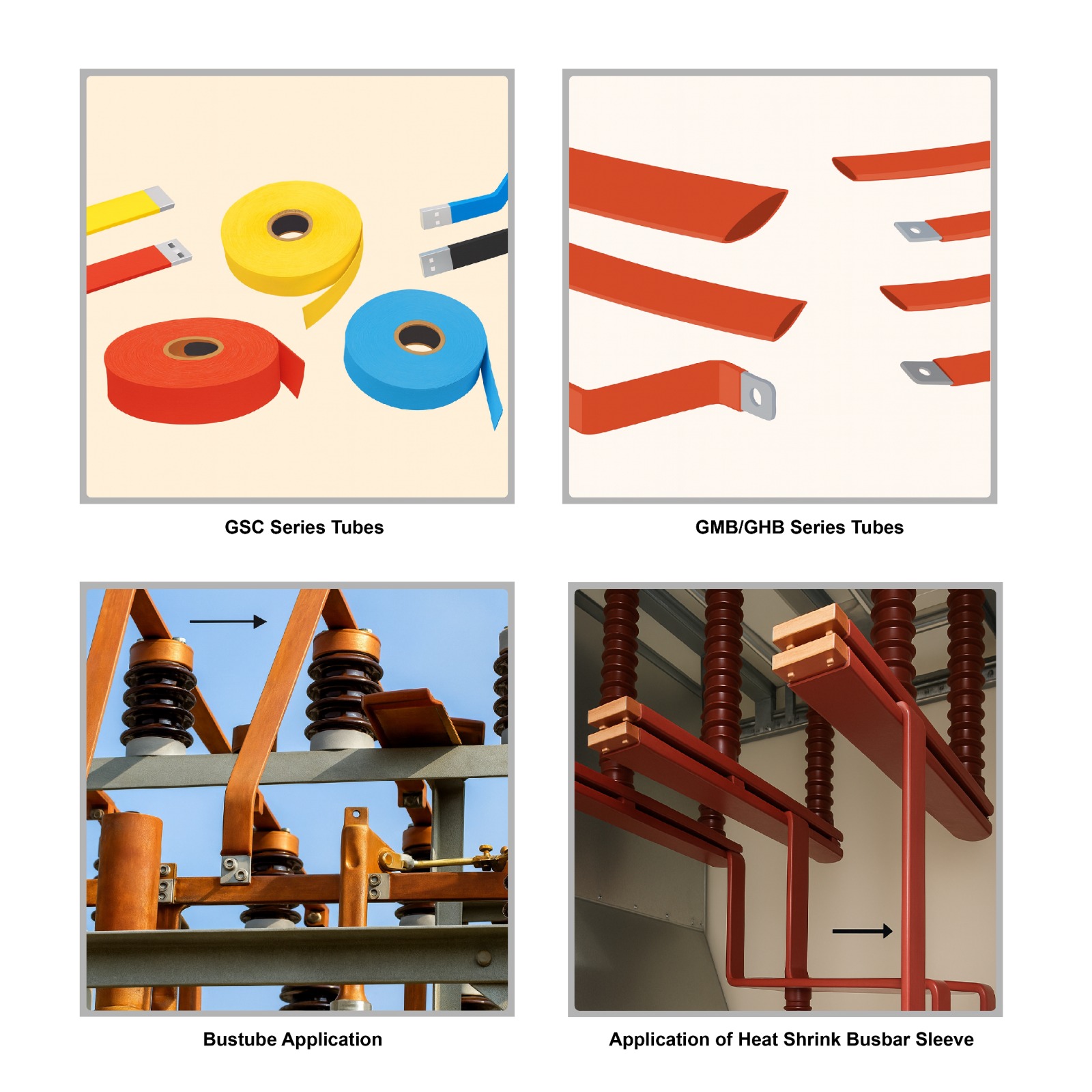

Heat Shrinkable Tubes/Heat Shrink Sleeves

Heat Shrink Bus Bar Sleeve

Bus Sleeve is heat shrinkable busbar Sleeve designed to insulate busbar system up to 36kV & to protect against accidental flash-over. The Sleeve are manufactured from high quality cross-linked polyolefin material. Meet ANSI C37.20.2 standard for MV switchgear application up to 36kV.

-: FEATURES & BENIFITS :-

- Reduce Busbar clearance.

- Prevent Busbar from chemical corrosion effected by strong acid, alkali, salt etc.

- Solve the problem of insulation among Busbar in Bus Duct.

- Halogen free, flame retardant.

- High dielectric strength.

- Highly Flexible for use on straight or angled bars without creasing.

Technical Qualification Report : QR 1019

SELECTION CHART

Thin Wall Tube [Up to 3.3KV]

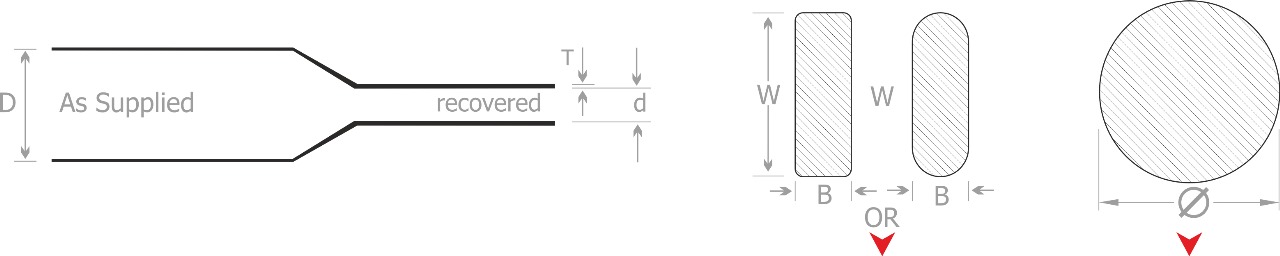

| Gala Size | D | d | T (±10% ) | Reel length | Rectangular Bars (W+B) | Round Bar Ø | ||

|---|---|---|---|---|---|---|---|---|

| mm(min.) | mm(max.) | mm | mtrs. | Min. | max. | Min. | max. | |

| GSC 16/8 | 16 | 8 | 0.69 | 100 | 16 | 18 | 12 | 12 |

| GSC 20/10 | 20 | 10 | 0.78 | 100 | 22 | 25 | 14 | 16 |

| GSC 30/15 | 30 | 15 | 0.86 | 50 | 33 | 38 | 21 | 24 |

| GSC 40/20 | 40 | 20 | 0.96 | 50 | 44 | 52 | 28 | 33 |

| GSC 50/25 | 50 | 25 | 0.96 | 25 | 53 | 65 | 34 | 41 |

| GSC 60/30 | 60 | 30 | 0.96 | 25 | 64 | 75 | 41 | 48 |

| GSC 70/35 | 70 | 35 | 1.10 | 25 | 72 | 90 | 46 | 57 |

| GSC 80/40 | 80 | 40 | 1.27 | 25 | 86 | 100 | 55 | 64 |

| GSC 100/50 | 100 | 50 | 1.40 | 25 | 104 | 125 | 66 | 80 |

| GSC 120/60 | 120 | 60 | 1.40 | 25 | 110 | 150 | 70 | 96 |

| GSC 150/75 | 150 | 75 | 1.40 | 25 | 151 | 190 | 96 | 121 |

| GSC 180/90 | 180 | 90 | 1.50 | 25 | 179 | 236 | 114 | 150 |

Medium Wall Tube [Upto 24KV]

| Gala Size | D | d | T (±10% ) | Reel length | Rectangular Bars (W+B) | Round Bar Ø | ||

|---|---|---|---|---|---|---|---|---|

| mm(min.) | mm(max.) | mm | mtrs. | Min. | max. | Min. | max. | |

| GMB 16/6 | 16 | 6 | 1.70 | 25 | 11 | 18 | 7 | 12 |

| GMB 25/10 | 25 | 10 | 2.50 | 25 | 16 | 30 | 12 | 20 |

| GMB 30/12 | 30 | 12 | 2.10 | 25 | 25 | 38 | 16 | 25 |

| GMB 40/16 | 40 | 16 | 2.10 | 25 | 33 | 50 | 21 | 32 |

| GMB 50/20 | 50 | 20 | 2.10 | 25 | 38 | 63 | 24 | 40 |

| GMB 65/25 | 65 | 25 | 2.20 | 25 | 53 | 82 | 34 | 52 |

| GMB 75/28 | 75 | 28 | 2.50 | 25 | 63 | 94 | 40 | 60 |

| GMB 85/32 | 85 | 32 | 2.50 | 25 | 69 | 107 | 44 | 68 |

| GMB 100/38 | 100 | 38 | 3.00 | 25 | 83 | 126 | 53 | 80 |

| GMB 120/45 | 120 | 45 | 3.00 | 25 | 104 | 150 | 66 | 96 |

| GMB 150/60 | 150 | 60 | 3.30 | 20 | 132 | 200 | 84 | 127 |

| GMB 180/72 | 180 | 72 | 3.00 | 20 | 151 | 226 | 96 | 144 |

| GMB 205/85 | 210 | 84 | 3.10 | 1.5 | 239 | 257 | 152 | 164 |

| GMB 250/100 | 250 | 100 | 3.10 | 1.5 | 264 | 314 | 168 | 200 |

Heavy Wall Tube [upto 36KV]

| Gala Size | D | d | T (±10% ) | Reel length | Rectangular Bars (W+B) | Round Bar Ø | ||

|---|---|---|---|---|---|---|---|---|

| mm(min.) | mm(max.) | mm | mtrs. | Min. | max. | Min. | max. | |

| GHB 25/8 | 25 | 8 | 3.20 | 25 | 20 | 28 | 13 | 20 |

| GHB 30/12 | 30 | 12 | 3.50 | 25 | 28 | 33 | 18 | 25 |

| GHB 40/16 | 40 | 16 | 3.50 | 25 | 35 | 45 | 22 | 32 |

| GHB 50/20 | 50 | 20 | 3.50 | 25 | 45 | 54 | 29 | 40 |

| GHB 65/25 | 65 | 25 | 3.50 | 25 | 50 | 62 | 32 | 43 |

| GHB 75/28 | 75 | 28 | 3.50 | 20 | 53 | 69 | 34 | 47 |

| GHB 85/32 | 85 | 32 | 3.50 | 20 | 69 | 100 | 44 | 68 |

| GHB 100/38 | 100 | 38 | 3.70 | 20 | 83 | 102 | 53 | 72 |

| GHB 120/45 | 120 | 45 | 3.70 | 20 | 94 | 125 | 60 | 85 |

| GHB 150/60 | 150 | 60 | 3.70 | 15 | 122 | 168 | 78 | 105 |

| GHB 180/70 | 180 | 70 | 3.70 | 15 | 160 | 196 | 102 | 125 |

| GHB 205/85 | 205 | 85 | 3.70 | 1.5 | 239 | 250 | 152 | 164 |

| GHB 250/120 | 250 | 120 | 4.20 | 1.5 | 264 | 314 | 168 | 200 |

TECHNICAL SPECIFICATION

- TEST DESCRIPTION

- RECORDED VALUE

- TEST METHOD

- Physical

- Tensile Strength

- 9 N/mm2 (MPA)(min.)

- ASTM D638

- Ultimate Elongation

- 350% (min.)

- ASTM D638

- Water Absorption

- 0.5 % (max.)

- ASTM D570

- Density

- 1.20 ± 0.2 gm/cm3

- ASTM D792

- Hardness

- 45 ± 10 shore D

- ASTM D2240

- Thermal

- Accelerated Ageing

- (150oC for 1200 Hrs)

- IEC 60684-2

- Tensile Strength

- 7.7 N/mm2 (Mpa)

- ASTM D 638

- Ultimate Elongation

- 300 % (Min.)

- ASTM D638

- Low temperature Flexibility

(-40oC for 4 Hrs.) - No Cracking

- ASTM D2671

- Heat Shock (250oC for 30 Min.)

- No Cracking or flowing

- ESI 09-11

- Shrink Temperature

- 125oC

- IEC 216

- Continuous Temperature limit

- -40oC to + 115oC

- IEC 216

- Electrical

- Dielectric Strength

- 22 KV/mm. (Min.)

- ASTM D149

- Volume Resistivity

- 1 x 1013 Ohm.cm(min.)

- ASTM D257

- Dielectric Constant

- 5 (Max.)

- ASTM D150

| CLEARANCE WITH INSULATION | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| VOLTAGE | MEDIUM WALL TUBE (GMB) | HEAVY WALL TUBE (GHB) | UN-INSULATED BUSBARS (mm) AS PER IEC 71-2 | ||||||

| PH to PH (mm) | PH to GR (mm) | PH to PH (mm) | PH to GR (mm) | ||||||

| Rectangular | Round | Rectangular | Round | Rectangular | Round | Rectangular | Round | ||

| 12 kV | 65 | 55 | 75 | 65 | 35 | 30 | 45 | 40 | 120 |

| 17.5 kV | 85 | 70 | 105 | 85 | 55 | 50 | 65 | 60 | 160 |

| 24 kV | 115 | 95 | 150 | 125 | 70 | 60 | 100 | 90 | 220 |

| 36 kV | 200 | 150 | 285 | 205 | 140 | 130 | 190 | 180 | 320 |

Products

Heat Shrink Tubes / Heat Shrink Sleeves

- Advantages Of Heat shrink Tubing

- Thin Wall Tubes

- GDW : Dual Wall Tubing

- Medium/Heavy Wall Tubes-Commercial

- Heat Shrink Co-extruded Tubing Premium Quality

- Red Insulation Tubes

- Non Tracking Tubes

- Busbar Sleeves

- Stress Control Tube

- Integrated Stress Control Tube-GVOT Tube

- Heat Shrink Double Layer Tube-GDTL Tube

- High Shrink Ratio Heat Shrink Tube

Switchgear Insulation Products

- Barrier Board Sheet

- End Sealing Kit for Extensible RMU/GIS Bushing

- Heat Shrink Bus Bar Sleeve

- Bus Bar Insulating Shrouds

- Bus Bar Insulating Shrouds Polyolefin

- Bus Bar End Caps

- Thin wall tube wire marking

- Heat Shrink Tape (Bustape)

- Insulation for Circuit Breakers

- Busbar Sleeve for 66 kV

- Bushing Boot

- Non Shrinkable High Voltage Tape

- Heat Shrinkable Gland

NEED ASSISTANCE?

Please contact us if you need help to understand our products & services