Polyolefin Overhead Line Cover (Insulcover)

Insulcover is a Wrap Around Line Cover that provides retrofit insulation for Overhead

Conductors to help prevent electrical outages caused by trees or wildlife coming into

the contact with distribution lines. It is manufactured from high quality Non-tracking

Cross-linked Polyolefin material. Gala Overhead Line Covers can be used in many

applications to enhance the insulation up to 400 kV. Insulcover is designed to insulate

existing bare lines without costly conductor replacement expenditure or additional line

hardware.

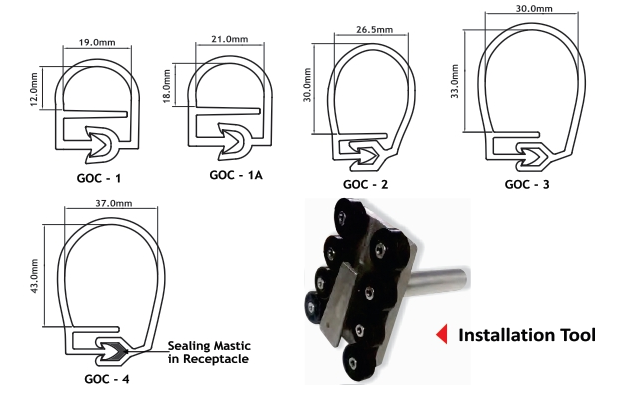

Installation is easy by using the Split Insulation Tube Tool which remains stationery at

single location.

FEATURES & BENEFITS:

- High Di-electric strength

- Excellent UV stabilized & weather resistant

- Passed 5000 Hrs. UV test

- Tracking & Erosion resistant

- Prevent Conductor from Chemical corrosion effected by strong acid, alkali, salt etc.

- Halogen free, Flame retardant

- Insulcover is available in five sizes that covers conductors up to 800 sq. mm.

| Selection Chart | |||

|---|---|---|---|

| Gala Code |

Conductor size in Dia. (mm) |

Packaging (Mtr./Roll) |

|

| GOC 1 | upto 10 | 30 | |

| GOC 1A | upto 15 | 30 | |

| GOC 2 | upto 22 | 30 | |

| GOC 3 | upto 28 | 30 | |

| GOC 4 | upto 38 | 30 | |

| Technical Specification | ||

|---|---|---|

| PROPERTIES | VALUE | TEST METHOD |

| Tensile Strength | 9 N/mm2 (Mpa) (min.) | ASTM D638 |

| Ultimate Elongation | 250% (min.) | ASTM D638 |

| Density | 1.20 ± 0.2gm/cm3 | ASTM D792 |

| Hardness | 40 ± 5 Shore D | ASTM D2240 |

| Water Absorption | 0.5% (max.) | ASTM D570 |

| Heat Shock (90°C for 4 hrs.) | No Cracking | ASTM D2671 |

| Flame Retardant | Pass | ASTM D2671 |

| Low Temperature Flexibility (-40°C for 4 hrs.) |

No Cracking | ASTM D2671 |

| Continuous Temperature Limit | -45°C to +105°C | IEC 216 |

| Dielectric Strength | 20kV/mm. (min.) | ASTM D149 |

| Volume Resistivity | 1 x 1013 Ohm.cm (min.) | ASTM D257 |

| Dielectric Constant | 5 (max.) | ASTM D150 |

| UV Resistance (5000 Hrs.) | No Colour Change | ASTM DG154 |

| Resistance to Tracking & Erosion | No Tracking, Erosion or Flame failure up to 3.25 kV for 20 min | ASTM D2303 |

* The above mentioned values are typical analytical values obtained on material When tested as per applicable standards under controlled laboratory conditions and should not be construed as specfications of the product.

Products

Heat Shrink Tubes / Heat Shrink Sleeves

- Advantages Of Heat shrink Tubing

- Thin Wall Tubes

- GDW : Dual Wall Tubing

- Medium/Heavy Wall Tubes-Commercial

- Heat Shrink Co-extruded Tubing Premium Quality

- Red Insulation Tubes

- Non Tracking Tubes

- Busbar Sleeves

- Stress Control Tube

- Integrated Stress Control Tube-GVOT Tube

- Heat Shrink Double Layer Tube-GDTL Tube

- High Shrink Ratio Heat Shrink Tube

Switchgear Insulation Products

- Barrier Board Sheet

- End Sealing Kit for Extensible RMU/GIS Bushing

- Heat Shrink Bus Bar Sleeve

- Bus Bar Insulating Shrouds

- Bus Bar Insulating Shrouds Polyolefin

- Bus Bar End Caps

- Thin wall tube wire marking

- Heat Shrink Tape (Bustape)

- Insulation for Circuit Breakers

- Busbar Sleeve for 66 kV

- Bushing Boot

- Non Shrinkable High Voltage Tape

- Heat Shrinkable Gland