Pipeline / Corrosion Protection Products

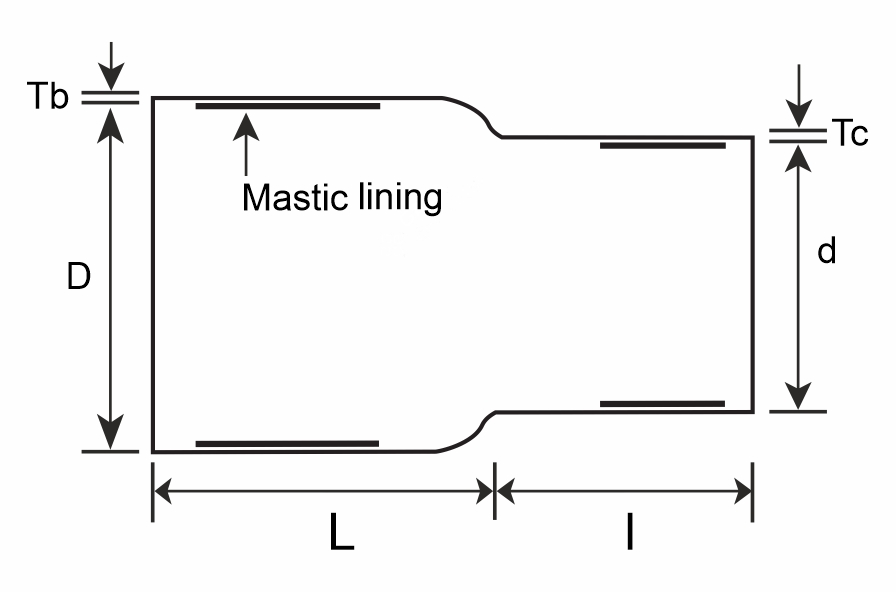

PRE-INSULATED PIPE SEALING CAP for Single Outlet

Pre-insulated Pipe Sealing Cap is Heat Shrink Cap with Hot Melt Adhesive / Mastic, used to seal and to protect the joints of pipeline and other substrates. The caps are manufactured from high quality Cross-linked Polyolefin material.

-: Features:-

- Excellent insulation end seal and provide maximum moisture protection.

- Provides watertight seal and prevents water access to the exposed insulation at the weld joint area.

- Provides corrosion protection to pipeline joints and other substrates.

- Hot melt adhesive lining provides 100% environmental sealing against weathering, moisture, contamination and adverse environmental conditions according to IP 68.

- Can be factory installed, once installed the Cap protects the pre-insulated pipe during transportation and storage.

- Reduces repairing cost.

- Resistance to UV rays & Ozone.

- Easy to install.

-: Applications:-

- Pre-insulated Pipes

- End Seal

- Water pipe Lines

- Oil & Gas

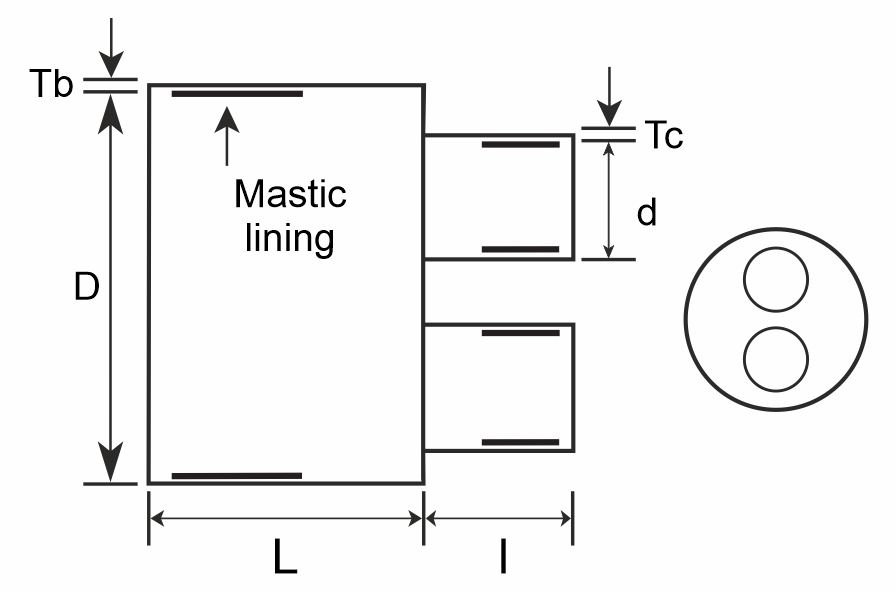

PRE-INSULATED PIPE SEALING CAP for Double Outlet

Pre-insulated Pipe Sealing Cap is Heat Shrink Cap with Hot Melt Adhesive / Mastic, used to seal and to protect the joints of pipeline and other substrates. The caps are manufactured from high quality Cross-linked Polyolefin material.

-: Features:-

- Excellent insulation end seal and provide maximum moisture protection.

- Provides watertight seal and prevents water access to the exposed insulation at the weld joint area.

- Provides corrosion protection to pipeline joints and other substrates.

- Hot melt adhesive lining provides 100% environmental sealing against weathering, moisture, contamination and adverse environmental conditions according to IP 68.

- Can be factory installed, once installed the Cap protects the pre-insulated pipe during transportation and storage.

- Reduces repairing cost.

- Resistance to UV rays & Ozone.

- Easy to install.

-: Applications:-

- Pre-insulated Pipes

- End Seal

- Water pipe Lines

- Oil & Gas

SELECTION CHART FOR SINGLE OUTLET

All dimensions are in mm

| Code | Ds | Df | ds | df | Ls | Lf | ls | lf | Tbf | Tcf | Mlb | Mlc |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min. | Max. | Min. | Max. | Min. | Min. | Min. | Min. | ±10% | ±10% | Min. | Min. | |

| GPPC1-1030 | 60 | 30 | 45 | 10 | 70 | 70 | 40 | 50 | 3.2 | 4.5 | 30 | 15 |

| GPPC1-1047* | 110 | 47 | 34 | 10 | 65 | 40 | 30 | 75 | 2.5 | 2.5 | 30 | 15 |

| GPPC1-1575* | 150 | 75 | 34 | 15 | 65 | 40 | 30 | 75 | 2.5 | 2.5 | 30 | 15 |

| GPPC1-2460-1 | 85 | 60 | 42 | 24 | 70 | 87 | 90 | 108 | 3.4 | 3.3 | 30 | 15 |

| GPPC1-2460-2 | 105 | 61 | 45 | 24 | 70 | 87 | 85 | 108 | 3.4 | 3.3 | 30 | 15 |

| GPPC1-2460-3 | 125 | 61 | 65 | 24 | 75 | 87 | 75 | 108 | 3.4 | 3.3 | 30 | 15 |

| GPPC1-2460-4 | 140 | 60 | 76 | 24 | 70 | 87 | 70 | 108 | 3.4 | 3.3 | 30 | 15 |

| GPPC1-2475-1 | 118 | 75 | 52 | 24 | 65 | 75 | 30 | 40 | 2.5 | 2.3 | 30 | 15 |

| GPPC1-2475-1A | 125 | 75 | 65 | 24 | 65 | 75 | 28 | 40 | 2.5 | 2.3 | 30 | 15 |

| GPPC1-2475-2 | 145 | 75 | 65 | 24 | 55 | 75 | 28 | 40 | 2.5 | 2.3 | 30 | 15 |

| GPPC1-2475-2A | 145 | 75 | 75 | 24 | 55 | 75 | 26 | 40 | 2.5 | 2.3 | 30 | 15 |

| GPPC1-2475-3 | 158 | 75 | 70 | 24 | 55 | 75 | 26 | 40 | 2.5 | 2.3 | 30 | 15 |

| GPPC1-3090-1 | 165 | 90 | 100 | 30 | 80 | 85 | 37 | 50 | 2.3 | 2.5 | 30 | 15 |

| GPPC1-3090-2 | 185 | 90 | 67 | 30 | 65 | 85 | 32 | 50 | 2.3 | 2.5 | 30 | 15 |

| GPPC1-3090-3 | 185 | 90 | 105 | 30 | 65 | 85 | 35 | 50 | 2.3 | 2.5 | 30 | 15 |

| GPPC1-3090-4 | 207 | 90 | 105 | 30 | 70 | 85 | 34 | 50 | 2.3 | 2.5 | 30 | 15 |

| GPPC1-4090-1 | 156 | 90 | 95 | 40 | 90 | 72 | 60 | 118 | 3.7 | 4.5 | 30 | 15 |

| GPPC1-4090-2 | 178 | 90 | 105 | 41 | 95 | 72 | 55 | 118 | 3.7 | 4.5 | 30 | 15 |

| GPPC1-53140* | 205 | 140 | 105 | 53 | 55 | 65 | 32 | 46 | 2.5 | 2.5 | 30 | 15 |

| GPPC1-68145-1* | 245 | 145 | 155 | 68 | 63 | 75 | 43 | 61 | 2.5 | 2.5 | 30 | 15 |

| GPPC1-68145-2* | 285 | 145 | 165 | 68 | 58 | 75 | 40 | 61 | 2.5 | 2.5 | 30 | 15 |

| GPPC1-120240-1* | 305 | 220 | 190 | 120 | 80 | 100 | 30 | 43 | 2.5 | 2.5 | 30 | 15 |

| GPPC1-120240-2* | 370 | 220 | 265 | 120 | 78 | 100 | 28 | 43 | 2.5 | 2.5 | 30 | 15 |

| GPPC1-225300 | 570 | 300 | 420 | 225 | 55 | 80 | 45 | 90 | 3.5 | 3.6 | 30 | 15 |

D, d : Internal Diameter | S : as Supplied | f : After Free Recovery | L, I : Length Tb, Tc : Thickness After Free Recovery | MIb : Mastic Length of Body | MIc : Mastic Length of Finger All dimensions are in mm.

SELECTION CHART FOR DOUBLE OUTLET

All dimensions are in mm

| Code | Ds | Df | ds | df | Ls | Lf | ls | lf | Tb | Tc | Mlb | Mlb |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min. | Max. | Min. | Max. | Min. | Min. | Min. | Min. | ±10% | ±10% | Min. | Min. | |

| GPPC2 1565S | 115 | 65 | 36 | 15 | 60 | 80 | 40 | 54 | 2.2 | 2.0 | 30 | 15 |

| GPPC2 1565 | 125 | 65 | 45 | 15 | 60 | 80 | 40 | 54 | 2.2 | 2.0 | 30 | 15 |

| GPPC2 1565A | 152 | 65 | 52 | 15 | 60 | 80 | 40 | 54 | 2.2 | 2.0 | 30 | 15 |

| GPPC2 1565AA | 156 | 65 | 45 | 15 | 60 | 80 | 40 | 54 | 2.2 | 2.0 | 30 | 15 |

| GPPC2 2075 | 175 | 75 | 60 | 20 | 80 | 105 | 45 | 80 | 3.1 | 2.9 | 30 | 15 |

| GPPC2 2075A | 200 | 75 | 60 | 20 | 80 | 105 | 45 | 80 | 3.1 | 2.9 | 30 | 15 |

| GPPC2 24135 | 235 | 135 | 68 | 24 | 80 | 160 | 50 | 70 | 2.8 | 2.5 | 30 | 15 |

| GPPC2 55175 | 265 | 175 | 86 | 55 | 80 | 130 | 50 | 65 | 3.5 | 3.5 | 30 | 15 |

| GPPC2 55175A | 300 | 175 | 100 | 55 | 80 | 130 | 50 | 65 | 3.5 | 3.5 | 30 | 15 |

| GPPC2 55175AA | 355 | 180 | 155 | 60 | 80 | 130 | 50 | 65 | 3.5 | 3.5 | 30 | 15 |

D, d : Internal Diameter | S : as Supplied | f : After Free Recovery | L, I : Length Tb, Tc : Thickness After Free Recovery | MIb : Mastic Length of Body | MIc : Mastic Length of Finger All dimensions are in mm.

TECHNICAL SPECIFICATION

| PROPERTIES | VALUE | STANDARD |

|---|---|---|

| Tensile Strength | 18 N/mm 2 (Mpa) (min.) | ASTM D638 |

| Ultimate Elongation | 450 % (min.) | ASTM D638 |

| Water absorption | 0.1 % (max.) | ASTM D570 |

| Hardness | 45 Shore D (min.) | ASTM D2240 |

| Accelerated ageing | (150 0 C for 168 hrs) | ASTM D2671 |

| Ultimate Elongaon | 320 % (min.) | ASTM D638 |

| Low Temp. Flexibility on 25mm | No cracking | ASTM D3111 |

| Mandrel (-40 0 C for 4 Hrs.) | ||

| Continuous Temperature Limit | -40 0 C to 125 0 C | IEC 216 |

| Adherence to the casing | 100 (max.) (@23 0 C 9N/cm) | Annex B |

| Adherence to the coating (3lpp) | 100 (max.) (@23 0 C 9N/cm) | Annex B |

| Shear Resistance (Adhesive) | 7 N/cm 2 (min.) | DIN 30672 |

| (@23 0 C 10mm/min.) | ||

| Softening Point (Adhesive) | 130 0 C (min.) | ASTM E28 |

| Adhesion / Peel Strength | 14 N/cm (min.) | ISO 21809-3 |

Products

Heat Shrinkable Moulded Shapes

Heat Shrink Tubes / Heat Shrink Sleeves

- Advantages Of Heat shrink Tubing

- Thin Wall Tubes

- GDW : Dual Wall Tubing

- Medium/Heavy Wall Tubes-Commercial

- Heat Shrink Co-extruded Tubing Premium Quality

- Red Insulation Tubes

- Non Tracking Tubes

- Busbar Sleeves

- Stress Control Tube

- Integrated Stress Control Tube-GVOT Tube

- Heat Shrink Double Layer Tube-GDTL Tube

Switchgear Insulation Products

- Barrier Board Sheet

- End Sealing Kit for Extensible RMU/GIS Bushing

- Heat Shrink Bus Bar Sleeve

- Bus Bar Insulating Shrouds

- Bus Bar Insulating Shrouds Polyolefin

- Bus Bar End Caps

- Thin wall tube wire marking

- Heat Shrink Tape (Bustape)

- Insulation for Circuit Breakers

- Busbar Sleeve for 66 kV

- Bushing Boot

- Non Shrinkable High Voltage Tape

- Heat Shrinkable Gland