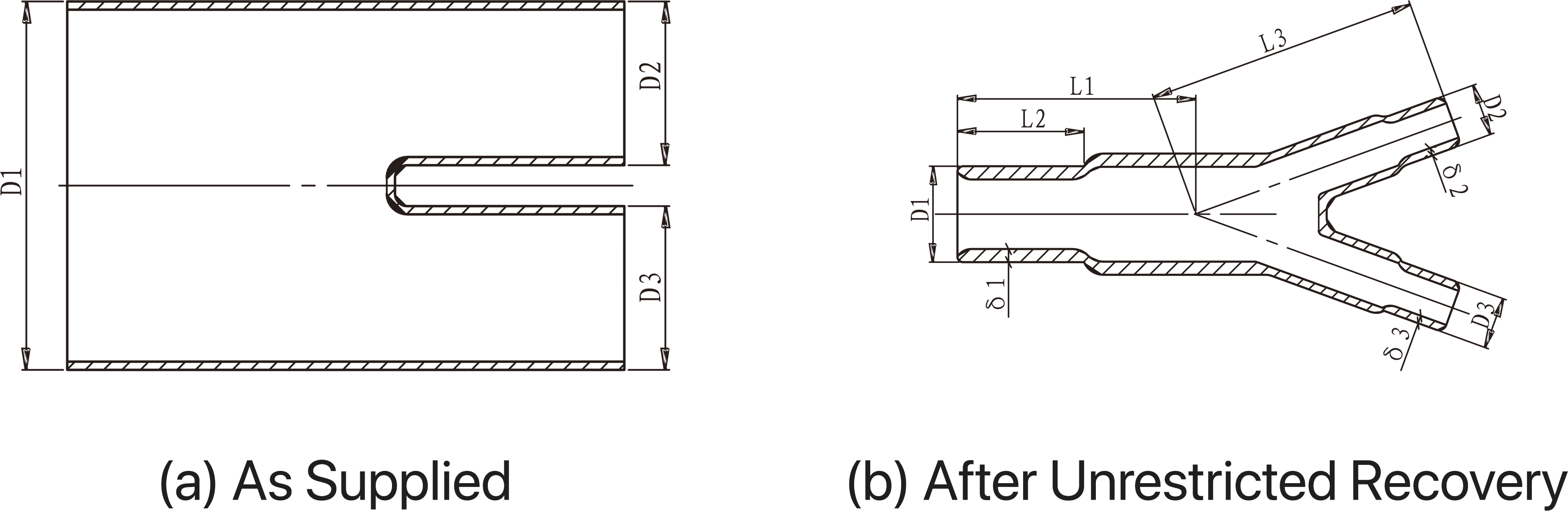

Heat Shrink 2 Way Boot

Heat Shrink Boots are manufactured from high quality cross-linked Polyolefin material conforming to stringent military specifications.

This boot provides an exceptional insulation, strain-relief & long term service reliability in connector joints of cable harness.

All dimesions are in mm

| Selection Chart | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Product Code | D1 | D2, 3 | L1 ±10% | L2 ±10% | L3 ±10% | T1 ±20% | T2, T3 ±20% | ||

| a (min) | b (max) | a (min) | b (max) | ||||||

| GHS2-N-306 | 13.5 | 6 | 6.6 | 3.3 | 24 | 15.5 | 25 | 2 | 1.5 |

| GHS2-N-612 | 27 | 12.4 | 13.2 | 6.1 | 53.3 | 33 | 55 | 2.5 | 2 |

| GHS2-N-1218 | 39 | 18 | 27 | 12.4 | 79 | 56 | 80 | 3 | 2.5 |

| Technical Specification | ||

|---|---|---|

| Property | Standard Value | Test Standard |

| Oxygen Index | ≥28% | ISO 4589 |

| Dielectric Strength | ≥20kV/mm | IEC 60243 |

| Physical Properties | ||

| Tensile Strength | ≥15MPa | ASTM-D-2671 |

| Elongation at Break | ≥500% | ASTM-D-2671 |

| Hardness (Shore A) | 90±2 | ISO 868 |

| Elongation at break after ageing (130°C, 168h) | ≥400% | ASTM-D-2671 |

| Heat Shock (200°C, 4h) | No dripping, flowing or cracking | UL 224 |

| Low temperature flexibility | -55°C | ISO 974 |

| Solvent Resistance (23°C, 24h) | ||

| Gasoline | ||

| Tensile strength | ≥11Mpa | ASTM-D-2671 |

| Elongation at break | ≥400% | ASTM-D-2671 |

| Diesel Oil | ||

| Tensile Strength | ≥10Mpa | ASTM-D-2671 |

| Elongation at break | ≥350% | ASTM-D-2671 |

| Acid & Alkali | ||

| Tensile Strength | ≥12Mpa | ASTM-D-2671 |

| Elongation at break | ≥400% | ASTM-D-2671 |

Products

Heat Shrink Tubes / Heat Shrink Sleeves

- Advantages Of Heat shrink Tubing

- Thin Wall Tubes

- GDW : Dual Wall Tubing

- Medium/Heavy Wall Tubes-Commercial

- Heat Shrink Co-extruded Tubing Premium Quality

- Red Insulation Tubes

- Non Tracking Tubes

- Busbar Sleeves

- Stress Control Tube

- Integrated Stress Control Tube-GVOT Tube

- Heat Shrink Double Layer Tube-GDTL Tube

- High Shrink Ratio Heat Shrink Tube

Switchgear Insulation Products

- Barrier Board Sheet

- End Sealing Kit for Extensible RMU/GIS Bushing

- Heat Shrink Bus Bar Sleeve

- Bus Bar Insulating Shrouds

- Bus Bar Insulating Shrouds Polyolefin

- Bus Bar End Caps

- Thin wall tube wire marking

- Heat Shrink Tape (Bustape)

- Insulation for Circuit Breakers

- Busbar Sleeve for 66 kV

- Bushing Boot

- Non Shrinkable High Voltage Tape

- Heat Shrinkable Gland