High Shrink Ratio Heat Shrink Tube

High-Shrink Ra o HS Tube (GMW 5x) is manufactured from high quality cross inked polyolefin material.

Application :

- Ideal for applications where there is a large dimensional difference between the cables, connectors and components.

- Enables the Tube to cover the large-size transi ons between cables, cable connectors and back shells, thus simplifying repairs of damaged cable as well as sealing the back end of the connectors.

Features & Benefits :

- High shrink ra o up to 5:1

- Optional hot melt adhesive lining for complete environmental protection and insulation

- Excellent resistance to weathering, UV rays, chemicals and solvents

- Meets RoHS Compliance | Halogen Free

- Meets IP 68 (Ingress Protec on)

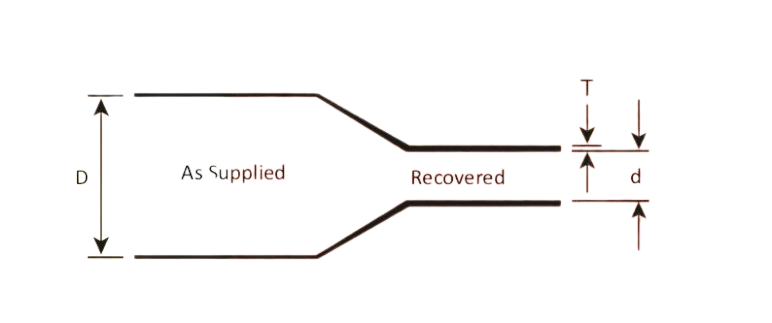

| Product Code | D min. (mm.) |

d max. (mm.) |

T +/- 10 % (mm.) |

|---|---|---|---|

| GMW 5x 30/6 | 30 | 6 | 4.3 |

| GMW 5x 40/8 | 40 | 8 | 4.3 |

| GMW 5x 50/10 | 50 | 10 | 4.3 |

| GMW 5x 60/12 | 60 | 12 | 4.5 |

| GMW 5x 75/15 | 75 | 15 | 4.5 |

| GMW 5x 90/18 | 90 | 18 | 4.5 |

| GMW 5x 105/21 | 105 | 21 | 5.0 |

| GMW 5x 115/23 | 115 | 23 | 5.0 |

| GMW 5x 130/26 | 130 | 26 | 5.0 |

| GMW 5x 140/28 | 140 | 28 | 5.0 |

| GMW 5x 160/32 | 160 | 32 | 5.0 |

Technical Specification

| PROPERTIES | VALUE | STANDARD |

|---|---|---|

| Physical | ||

| Tensile Strength | 12 N/mm2 (Mpa)(min.) | ASTM D638 |

| Ultimate Elongation | 350 % (min) | ASTM D638 |

| Density | 1.0 ± 0.2 gm/cm3 | ASTM D792 |

| Longitudinal Change | -10% (max.) | ASTM D2671 |

| Hardness | 45 ±10 Shore D | ASTM D2240 |

| Water Absorption | 0.5 % (max.) | ASTM D570 |

| Thermal | ||

| Accelerated ageing | (150°C for 168 Hrs.) | ASTM D2671 |

| Tensile Strength | 10 N/mm2 (Mpa)(min.) | ASTM D638 |

| Ultimate Elongation | 300% (min.) | ASTM D638 |

| Low Temperature Flexibility (-40°C for 4 hrs.) |

No Cracking | ASTM D2671 |

| Heat Shock (250°C for 30 Min.) | No Cracking or Flowing | ESI 09-11 | Shrink Temperature | 125°C | IEC 216 |

| Continuous Temperature Limit | -40 to +110°C | IEC 216 |

| Electrical | ||

| Dielectric Strength (2mm Wall) | 12 kV/mm. (min.) | ASTM D149 |

| Volume Resistivity | 1 x 1012 Ohm.cm (min.) | ASTM D257 |

| Dielectric constant | 5 (max.) | ASTM D150 |

| Weathering : The material from which Medium and Heavy wall tubings are manufactured contains carbon black to protect it from UV light. | ||

Products

Heat Shrink Tubes / Heat Shrink Sleeves

- Advantages Of Heat shrink Tubing

- Thin Wall Tubes

- GDW : Dual Wall Tubing

- Medium/Heavy Wall Tubes-Commercial

- Heat Shrink Co-extruded Tubing Premium Quality

- Red Insulation Tubes

- Non Tracking Tubes

- Busbar Sleeves

- Stress Control Tube

- Integrated Stress Control Tube-GVOT Tube

- Heat Shrink Double Layer Tube-GDTL Tube

- High Shrink Ratio Heat Shrink Tube

Switchgear Insulation Products

- Barrier Board Sheet

- End Sealing Kit for Extensible RMU/GIS Bushing

- Heat Shrink Bus Bar Sleeve

- Bus Bar Insulating Shrouds

- Bus Bar Insulating Shrouds Polyolefin

- Bus Bar End Caps

- Thin wall tube wire marking

- Heat Shrink Tape (Bustape)

- Insulation for Circuit Breakers

- Busbar Sleeve for 66 kV

- Bushing Boot

- Non Shrinkable High Voltage Tape

- Heat Shrinkable Gland