Heat Shrink Boots - Military Boots

Heat Shrink Straight Boot - Lipped

Heat Shrink Boots are manufactured from high quality cross-linked Polyolefin material conforming to stringent military specifications.

This boot provides an exceptional insulation, strain-relief & long term service reliability in connector joints of cable harness.

Features / Benefits:

- Excellent Electrical strength & Mechanical toughness

- Excellent resistance to weathering, UV rays, Chemicals, Oils, Fuels & Solvents

- Flame retardant & Self extinguishing

- High shrink ratio, shrink temperature 120°C

- Easy to install even on connector, already mounted to cable

- Not melting and resistant to cold flow

- Wide operating temperature range

SELECTION CHART

All dimensions are in mm.

| Product Code | H | H | J | J | P | R | U | JO | HW | JW | X | Y |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| a | b | a | b | b | b | b | b | b | b | b | b | |

| (min) | (max) | (min) | (max) | (±10%) | (±10%) | (±10%) | (±10%) | (±20%) | (±20%) | (±20%) | (±20%) | |

| GHSB-111 | 25.60 | 10.30 | 23.80 | 4.70 | 38.00 | 21.20 | 10.00 | 8.30 | 2.00 | 1.20 | 18.00 | 13.00 |

| GHSB-714 | 32.00 | 14.00 | 32.00 | 7.00 | 65.00 | 36.00 | - | 17.00 | 1.80 | 1.80 | - | - |

| GHSB 202-4 | 37.00 | 20.00 | 37.00 | 8.40 | 76.00 | 46.00 | - | 14.50 | 1.70 | 1.30 | - | - |

TECHNICAL SPECIFICATION

- PROPERTIES

- TYPICAL VALUE

- STANDARD

- Tensile Strength

- 9.5 N/mm2 (MPA)(min.)

- ASTM D412

- Ultimate Elongation

- 250 % (min)

- ASTM D412

- Water Absorption

- 0.5 % (max.)

- ASTM D570

- Thermal Ageing

- (175°C for 168 hrs)

- ASTM D2671

- Tensile Strength

- 8.5 N/mm2 (Mpa) (min.)

- ASTM D412

- Ultimate Elongation

- 200%(Min.)

- ASTM D638

- Low temp. Flexibility

- No Cracking

- ASTM D2671

- Heat Shock (250oC for 30 Min.)

- No Cracking or Dripping

- ASTM D2671

- Flammability

- Self Extinguishing

- ASTM D2671

- Dielectric Strength

- 10 kV/mm.(min)

- ASTM D149

- Volume Resistivity

- 1 x 1012 Ohm.cm (min)

- ASTM D257

- Corrosion Resistance

- Non Corrosive

- ASTM D2671

- Resistance to Chemicals,

- Good

- MIL-I-81765A

- Solvents, Oils & Lubricants

- Fungus Resistance

- No Growth

- ASTM G-21

Heat Shrink Right Angle Boot - Lipped

Heat Shrink Boots are manufactured from high quality cross-linked Polyolefin material conforming to stringent military specifications.

This boot provides an exceptional insulation, strain-relief & long term service reliability in connector joints of cable harness.

Features / Benefits:

- Excellent Electrical strength & Mechanical toughness

- Excellent resistance to weathering, UV rays, Chemicals, Oils, Fuels & Solvents

- Flame retardant & Self ex

- High shrink ratio, shrink temperature 120°C

- Easy to install even on connector, already mounted to cable.

- Not melting and resistant to cold flow

- Wide operating temperature range

SELECTION CHART

All dimensions are in mm.

| Product Code | H | H | J | J | P | R | JO | HW | JW | X | Y |

|---|---|---|---|---|---|---|---|---|---|---|---|

| a | b | a | b | b | b | b | b | b | b | b | |

| (min) | (max) | (min) | (max) | (±10%) | (±10%) | (±10%) | (±20%) | (±20%) | (±20%) | (±20%) | |

| GHRB-111 | 25.70 | 10.50 | 22.00 | 4.80 | 24.50 | 25.00 | 8.10 | 2.00 | 1.00 | 16.00 | 14.00 |

| GHRB-151 | 43.00 | 26.00 | 41.00 | 10.00 | 52.00 | 44.00 | 17.50 | 3.00 | 1.00 | 25.00 | 25.00 |

TECHNICAL SPECIFICATION

- PROPERTIES

- TYPICAL VALUE

- STANDARD

- Tensile Strength

- 9.5 N/mm2 (MPA)(min.)

- ASTM D412

- Ultimate Elongation

- 250 % (min)

- ASTM D412

- Water Absorption

- 0.5 % (max.)

- ASTM D570

- Thermal Ageing

- (175°C for 168 hrs)

- ASTM D2671

- Tensile Strength

- 8.5 N/mm2 (Mpa) (min.)

- ASTM D412

- Ultimate Elongation

- 200%(Min.)

- ASTM D638

- Low temp. Flexibility

- No Cracking

- ASTM D2671

- Heat Shock (250oC for 30 Min.)

- No Cracking or Dripping

- ASTM D2671

- Flammability

- Self Extinguishing

- ASTM D2671

- Dielectric Strength

- 10 kV/mm.(min)

- ASTM D149

- Volume Resistivity

- 1 x 1012 Ohm.cm (min)

- ASTM D257

- Corrosion Resistance

- Non Corrosive

- ASTM D2671

- Resistance to Chemicals,

- Good

- MIL-I-81765A

- Solvents, Oils & Lubricants

- Fungus Resistance

- No Growth

- ASTM G-21

Heat Shrink Boot - Y Type

Heat Shrink Boots are manufactured from high quality cross-linked Polyolefin material conforming to stringent military specifications.

This boot provides an exceptional insulation, strain-relief & long term service reliability in connector joints of cable harness.

Features / Benefits:

- Excellent Electrical strength & Mechanical toughness

- Excellent resistance to weathering, UV rays, Chemicals, Oils, Fuels & Solvents

- Flame retardant & Self ex

- High shrink ratio, shrink temperature 120°C

- Easy to install even on connector, already mounted to cable.

- Not melting and resistant to cold flow

- Wide operating temperature range

- Product is type tested as per Military Specification - SAE AS 81765/1

SELECTION CHART

All dimensions are in mm.

| Product Code | H | J | K | P | R&S | W | |||

|---|---|---|---|---|---|---|---|---|---|

| a(min) | b(max) | a(min) | b(max) | a(min) | b(max) | b(±10%) | b(±10%) | b(±20%) | |

| GHYB-381-1 | 19.80 | 6.60 | 13.20 | 6.60 | 13.20 | 6.60 | 40.60 | 40.60 | 1.50 |

TECHNICAL SPECIFICATION

- PROPERTIES

- TYPICAL VALUE

- STANDARD

- Tensile Strength

- 9.5 N/mm2 (MPA)(min.)

- ASTM D412

- Ultimate Elongation

- 250 % (min)

- ASTM D412

- Water Absorption

- 0.5 % (max.)

- ASTM D570

- Thermal Ageing

- (175°C for 168 hrs)

- ASTM D2671

- Tensile Strength

- 8.5 N/mm2 (Mpa) (min.)

- ASTM D412

- Ultimate Elongation

- 200%(Min.)

- ASTM D638

- Low temp. Flexibility

- No Cracking

- ASTM D2671

- Heat Shock (250oC for 30 Min.)

- No Cracking or Dripping

- ASTM D2671

- Flammability

- Self Extinguishing

- ASTM D2671

- Dielectric Strength

- 10 kV/mm.(min)

- ASTM D149

- Volume Resistivity

- 1 x 1012 Ohm.cm (min)

- ASTM D257

- Corrosion Resistance

- Non Corrosive

- ASTM D2671

- Resistance to Chemicals,

- Good

- MIL-I-81765A

- Solvents, Oils & Lubricants

- Fungus Resistance

- No Growth

- ASTM G-21

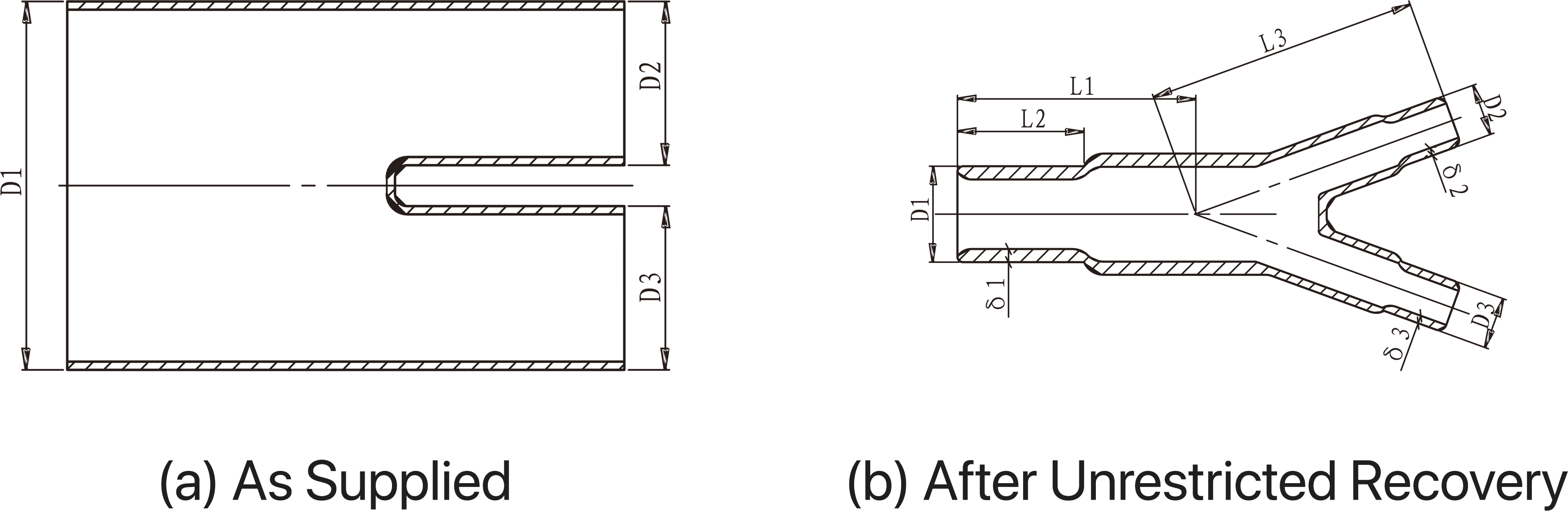

Heat Shrink 2 Way Boot

Heat Shrink Boots are manufactured from high quality cross-linked Polyolefin material conforming to stringent military specifications.

This boot provides an exceptional insulation, strain-relief & long term service reliability in connector joints of cable harness.

All dimesions are in mm

| Selection Chart | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Product Code | D1 | D2, 3 | L1 ±10% | L2 ±10% | L3 ±10% | T1 ±20% | T2, T3 ±20% | ||

| a (min) | b (max) | a (min) | b (max) | ||||||

| GHS2-N-306 | 13.5 | 6 | 6.6 | 3.3 | 24 | 15.5 | 25 | 2 | 1.5 |

| GHS2-N-612 | 27 | 12.4 | 13.2 | 6.1 | 53.3 | 33 | 55 | 2.5 | 2 |

| GHS2-N-1218 | 39 | 18 | 27 | 12.4 | 79 | 56 | 80 | 3 | 2.5 |

| Technical Specification | ||

|---|---|---|

| Property | Standard Value | Test Standard |

| Oxygen Index | ≥28% | ISO 4589 |

| Dielectric Strength | ≥20kV/mm | IEC 60243 |

| Physical Properties | ||

| Tensile Strength | ≥15MPa | ASTM-D-2671 |

| Elongation at Break | ≥500% | ASTM-D-2671 |

| Hardness (Shore A) | 90±2 | ISO 868 |

| Elongation at break after ageing (130°C, 168h) | ≥400% | ASTM-D-2671 |

| Heat Shock (200°C, 4h) | No dripping, flowing or cracking | UL 224 |

| Low temperature flexibility | -55°C | ISO 974 |

| Solvent Resistance (23°C, 24h) | ||

| Gasoline | ||

| Tensile strength | ≥11Mpa | ASTM-D-2671 |

| Elongation at break | ≥400% | ASTM-D-2671 |

| Diesel Oil | ||

| Tensile Strength | ≥10Mpa | ASTM-D-2671 |

| Elongation at break | ≥350% | ASTM-D-2671 |

| Acid & Alkali | ||

| Tensile Strength | ≥12Mpa | ASTM-D-2671 |

| Elongation at break | ≥400% | ASTM-D-2671 |

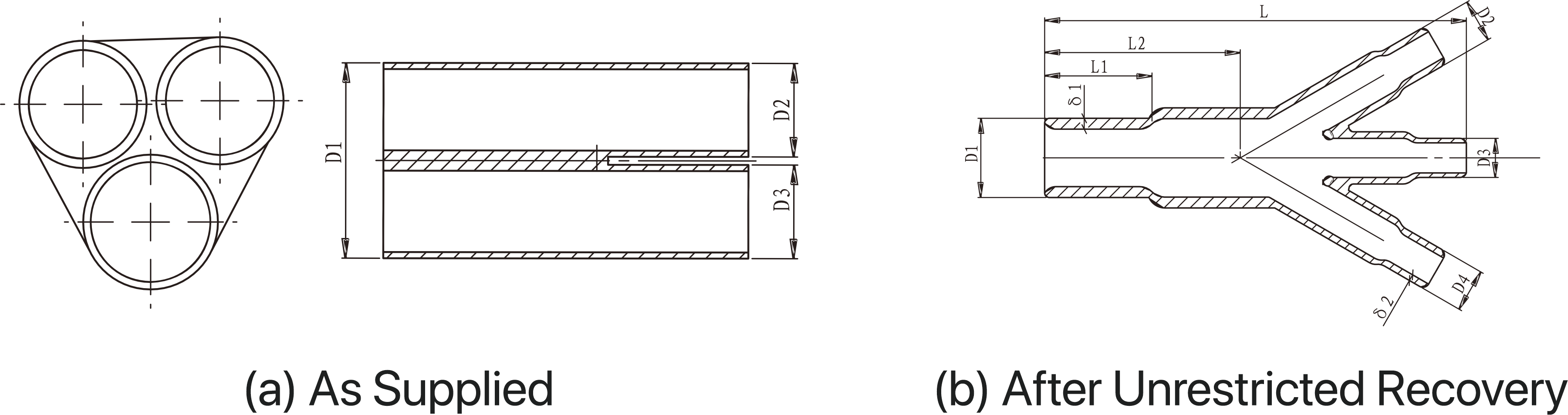

Heat Shrink 3 Way Boot

Heat Shrink Boots are manufactured from high quality cross-linked Polyolefin material conforming to stringent military specifications.

This boot provides an exceptional insulation, strain-relief & long term service reliability in connector joints of cable harness.

All dimesions are in mm

| Selection Chart | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Product Code | D1 | D2, 3 | L1 ±10% | L2 ±10% | L3 ±10% | T1 ±20% | T2, T3 ±20% | ||

| a (min) | b (max) | a (min) | b (max) | ||||||

| GHS3-N-407 | 14 | 6.6 | 6.6 | 3.6 | 46 | 31 | 15.7 | 2 | 1.5 |

| Technical Specification | ||

|---|---|---|

| Property | Standard Value | Test Standard |

| Oxygen Index | ≥28% | ISO 4589 |

| Dielectric Strength | ≥20kV/mm | IEC 60243 |

| Physical Properties | ||

| Tensile Strength | ≥15MPa | ASTM-D-2671 |

| Elongation at Break | ≥500% | ASTM-D-2671 |

| Hardness (Shore A) | 90±2 | ISO 868 |

| Elongation at break after ageing (130°C, 168h) | ≥400% | ASTM-D-2671 |

| Heat Shock (200°C, 4h) | No dripping, flowing or cracking | UL 224 |

| Low temperature flexibility | -55°C | ISO 974 |

| Solvent Resistance (23°C, 24h) | ||

| Gasoline | ||

| Tensile strength | ≥11Mpa | ASTM-D-2671 |

| Elongation at break | ≥400% | ASTM-D-2671 |

| Diesel Oil | ||

| Tensile Strength | ≥10Mpa | ASTM-D-2671 |

| Elongation at break | ≥350% | ASTM-D-2671 |

| Acid & Alkali | ||

| Tensile Strength | ≥12Mpa | ASTM-D-2671 |

| Elongation at break | ≥400% | ASTM-D-2671 |

Products

Heat Shrinkable Moulded Shapes

Heat Shrink Tubes / Heat Shrink Sleeves

- Advantages Of Heat shrink Tubing

- Thin Wall Tubes

- GDW : Dual Wall Tubing

- Medium/Heavy Wall Tubes-Commercial

- Heat Shrink Co-extruded Tubing Premium Quality

- Red Insulation Tubes

- Non Tracking Tubes

- Busbar Sleeves

- Stress Control Tube

- Integrated Stress Control Tube-GVOT Tube

- Heat Shrink Double Layer Tube-GDTL Tube

- High Shrink Ratio Heat Shrink Tube

Switchgear Insulation Products

- Barrier Board Sheet

- End Sealing Kit for Extensible RMU/GIS Bushing

- Heat Shrink Bus Bar Sleeve

- Bus Bar Insulating Shrouds

- Bus Bar Insulating Shrouds Polyolefin

- Bus Bar End Caps

- Thin wall tube wire marking

- Heat Shrink Tape (Bustape)

- Insulation for Circuit Breakers

- Busbar Sleeve for 66 kV

- Bushing Boot

- Non Shrinkable High Voltage Tape

- Heat Shrinkable Gland